Unveil the Mysteries of the Universe with Vacuum Solutions

Ask the question, search for the answer. INFICON is the key to the solution.

INFICON supports Research & Academia in its endeavors by delivering cutting-edge technologies in vacuum sensing and control, ultra-sensitive leak detection, precise residual gas analysis, and sub-nanometer surface engineering via Atomic Layer Deposition.

With a long-standing history of supplying high-end instruments to a broad spectrum of Research and Big Science applications such as Particle Accelerators, Nuclear Fusion, Space Simulation, Astrophysics, Cosmology and Fundamental Physics, INFICON’s solutions are shaped by decades of expertise in vacuum measurement and a pioneering spirit for innovation.

Vacuum Control

At INFICON, we develop, produce and lead innovation for accurate and reliable vacuum measurement solutions to advanced vacuum-based processes.

Our comprehensive vacuum measurement portfolio offers versatile sensing capabilities. While active vacuum gauges are the all-around solutions for industrial or laboratory needs and calibration stands, our passive gauges and controllers are engineered to perform reliably down to Ultra-High Vacuum (UHV) and under extreme conditions, including high bake-out temperatures, harsh ionizing radiation, and strong magnetic fields with minimal stray interference.

- Experts in Precise Vacuum Measurement: Our Capacitance Diaphragm Gauges (e.g. SKY® CDG025D) provide direct pressure measurement with outstanding accuracy, stability and gas type independency.

- Experts in Wide Range Vacuum Measurement: With our vast selection of measurement principles and our modular sensor designs, vacuum can be monitored and controlled across 15 decades of pressure, from 10-12 mbar to atmosphere.

- Gauge Controllers: Along to our long-standing expertise in sensor development, we in-house develop advanced Active & Passive Gauge Controllers equipped with the latest industrial communication protocols (PROFINET, PROFIBUS, etc.) and control logics.

- Vacuum Components: Our portfolio of solutions is rounded up by high and ultra-high vacuum fittings, feedthroughs and viewports, manufactured according to the highest international quality standards and with UHV cleanliness levels.

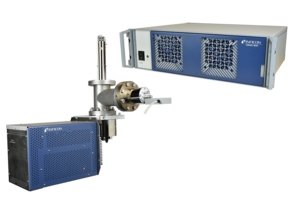

A long-standing family tradition: VGC094

Thanks to our expertise in meeting the most stringent requirements, we are leaders in passive sensing technology. The high-performance VGC094 passive Vacuum Gauge Controller is the globally recognized solution in Big Science for applications requiring the highest performance, such as operation from long distance, high temperatures or high ionizing radiation exposure.

Compatible with the wide range of INFICON passive gauges, like PSG01x Pirani gauges, MAG070 and the innovative magnetic field resistant MAG084 and MAG086 Cold Cathode gauges, VGC094 is able to monitor and control the entire vacuum pressure range from 1×10-11 mbar to atmosphere.

Residual Gas Analysis

Residual Gas Analysis is an essential technique required by large-scale instruments as well as laboratory vacuum systems. Partial pressure measurement with quadrupole mass spectrometers (QMS) is key to enable accurate identification and quantification of gas species within ultraclean vacuum systems.

- Ensuring vacuum cleanliness: With Minimum Detectable Partial Pressures down to 1×10-15 mbar, our Transpector MPH and the ultra-sensitive QMG 800 gas analysers ensure your vacuum system is qualified and commissioned free of undesired hydrocarbon gases and contamination.

- Real-time gas partial pressure monitoring: Fast gas sampling and analysis (up to 1.8 ms per point) help measuring the distribution and evolution of specific gas species, e.g. during operation (essential for next-gen Fusion reactors).

- Impurities control: With high pressure operation up to atmosphere (Transpector® CPX), detection of unexpected gas ingress or evolving gases source from materials (thermal outgassing, degassing of gas species due to photons or charged particles, etc.) is always under control.

- Checking gas inventories: With precision down to the part-per-billion (ppb), quadrupole mass spectrometers support the quantification and control of the different gas species and their partial pressures during in cyclic processes such as in accumulation pumped systems (e.g. cryogenic vacuum systems) or fusion machines.

High-end Quadrupole Mass Spectrometers: Transpector® MPH and QMG800

Having even flown to the Moon, Transpector® MPH is a world leader RGA that enables accurate process monitoring and control, essential for optimizing experimental research conditions and maximizing data accuracy. It offers high-performance gas analysis with industry-leading data collection speed, minimum detectable partial pressure (MDPP) and superior signal-to-noise ratio. It can be equipped with either a Faraday Cup or Electron Multiplier detector and offers an optional calibration reference for easy, automatic mass-scale tuning. Its ion source incorporates two filaments, allowing for extended operation and minimizing unexpected system downtime.

QMG 800 is the next-generation analytical mass spectrometer for high-performance gas analysis. Relying on the robust design of the QMA 400 series sensor, this updated Quadrupole Mass Spectrometer builds strong on the legacy of successes of the QMG 700 and now offers the latest communication protocols and FabGuard compatibility. It is the ideal choice for accurate analysis of contamination and for the qualification of ultraclean vacuum systems, ensuring the highest levels of purity and quality control. With five ion source design options, QMG 800 offers unparalleled precision and sensitivity up to single ion detection capabilities and industry-leading measurement speeds of 125 microseconds per AMU.

Leak Detection and Testing

Leak detection is an essential quality control step in manufacturing of large components for Big Science instruments. Leak monitoring of vacuum systems during operations is crucial for maintaining vacuum integrity. This reduces potential downtime and ensures consistent operational performance.

Precise leak detection is the primary requirement for reaching Ultra-High Vacuum conditions. Leak detectors are employed to perform Quality Assurance at component level prior installation. Quick pumping and sophisticated algorithms allow detecting and localizing leaks in gigantic complex vacuum systems, sometimes as large as 4-story building. In Fusion reactors, leak detection and localization are essential operational techniques adopted to ensure the confinement of radioactive (e.g. Tritium) sources. In large systems, leak monitoring of vacuum systems during operations is crucial for maintaining vacuum integrity. This reduces potential downtime and ensures consistent operational performance.

Integral (“global”) leak testing

- Pumping of large volumes: Large pumping speed and optimized helium pumping speed with high helium compression at all pressures, offered by UL3000 and UL6000 Fab Series, are essential to deliver high sensitivity, quick response time, and fast clean-up.

- Short response times: A long path between the leak source and the leak detection port may hinder response time during leak detection. Smart algorithms such as I·BOOST and SPRAY-Check provide intelligent software solutions that allow saving time of up to 50% when searching for and locating leaks.

- Low background and noise reduction: The capability to detect against large “background” noise (caused e.g. by water outgassing) calls for high sensitivity and special signal filtering techniques (intelligent calculation algorithm for leak rates), such as HYDRO-S and I-CAL.

- Different tracer gas: The adoption of different tracer gases forms a viable alternative to she scarce abundance of helium and its rising costs. INFICON offers a wide range of hydrogen leak detectors designed to excel in a variety of industrial applications.

Leak localization

- Precise and user-friendly leak checking: Portable helium spray sources like SMART-Spray may transform your leak detection process. They are the ideal tool when testing cumbersome geometries or large surfaces.

- Connectivity and real time information: Integrated or wireless connected displays like the RC1000 Remote Control provide a clear status to operator throughout the leak detection.

Smart leak testing with the UL Family of Leak Detectors

Our UL1000, UL3000 and UL6000 Fab Series leak detectors provide flexibility, high sensitivity and quick accurate results, making any leak detection fast and effective.

The UL1000 series is the best compromise between high performance, unparalleled robustness, and affordability. It delivers state-of-the art detection limits of 10-12 mbar∙l/s combined with reasonable short pump down and response time.

With faster pump down time and the HYDRO·S function allowing start leak checking in water vapor background, UL3000 Fab/UL3000 Fab ULTRA make it possible to quickly reach sensitive measurement ranges. Its slim design provides easy maneuverability and lower total cost of ownership due to the integrated low maintenance roots roughing pump and robust ion source.

With its highest sensitivity and fastest response time, the UL6000 Fab/UL6000 Fab PLUS series sets a new standard in precise leak detection. A booster turbomolecular pump provides extremely fast response on the largest volumes. The main special multiple inlet turbomolecular pump has optimized high helium pumping speeds with high helium compression at all pressures that delivers excellent sensitivity, response, and fast clean-up. Self-protection features protect the UL6000 against unintentional shock venting or helium/particulate contamination.

SMART Functions

- I∙CAL

Time-saving software algorithm, reduces noise to a minimum without missing details such as the slightest real signal peak - I∙ZERO 2.0

Low helium background in the briefest time, reliably detects even the smallest leaks - MASSIVE MODE

Leak testing beginning at atmospheric pressure, spray method detects large leaks as well - HYDRO∙S

Eliminates the water content in the signal to quickly reach a low background at the beginning of the test - I∙CHECK

Measures helium concentration in the environment to ensure optimum measurement conditions - I·RISE

Provides in-device rate-of-rise measurement combined with helium spraying method

SMART Spray Helium Spray Gun enhances leak checking and localization by eliminating the need for large helium cylinders and cumbersome hoses. It streamlines the process, reducing manual helium flow adjustments and minimizing errors. This tool makes leak detection faster, easier, more reliable and more effective while saving precious and costly helium tracer gas. It is the modern solution for efficient and precise leak testing while maintaining low helium consumption and background levels.

Sub-nanometer surface engineering via Atomic Layer Deposition

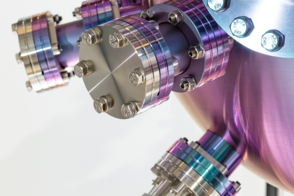

The INFICON xParts are Atomic Layer Deposition (ALD) coatings for 3D parts made for functional sub-nanometer surface engineering. xParts coatings are highly uniform, particle free, ALD thin films applied on standard fittings or customer-specific three-dimensional parts.

Components coated with xParts offer high corrosion resistance to harsh chemicals, resulting in a longer lifetime and lower cost of ownership. xParts may provide a pin-hole free, stable diffusion barrier, which reduces the need for conditioning and helps maintain consistent process performance. Materials coated with xParts exhibit low contamination: they are engineered to be particle-free, reducing particle-related issues and enabling fewer defects and faster recovery after preventive maintenance.

Related Articles

INFICON Transpector® MPH quadrupole mass spectrometer successfully landed and operated on the lunar surface.

Gas detection technology from INFICON helps us better understand volcanic activity and protect lives.

Our mission is to help protect human life and resources from the consequences of natural disasters by using our gas sensing technology to enable key research at academic and government institutions to understand better what nature is telling us.