Five Key Applications for Residual Gas Analyzers

RGAs play a vital role in semiconductor vacuum applications by supporting precision, reliability, and contamination control.

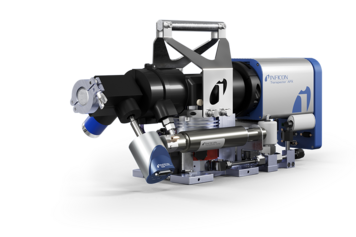

Residual gas analyzers (RGAs) are essential tools in vacuum systems and analytical instrumentation. INFICON has been building them for nearly 50 years, including the world’s first RGA to work at extended pressure ranges, along with many other innovations.

Our RGAs’ ability to detect and quantify trace gases makes them invaluable in semiconductor manufacturing. Here are five key applications where RGAs make a measurable impact in the factory:

- Leak Detection | RGAs can identify even the smallest leaks by detecting trace gases like helium or water vapor. This is critical where maintaining ultra-clean vacuum environments is essential for yield and performance.

- Process Characterization and Background Monitoring | By establishing baseline gas levels in a process chamber, RGAs help characterize the background environment. Once these baselines are set, the RGA monitors for deviations, ensuring consistency and stability throughout the process.

- Process Monitoring | During processes like chemical vapor deposition or plasma etching, RGAs monitor gas composition in real time to help ensure process consistency, detect contamination, and optimize throughput.

- Contamination Control | RGAs identify unexpected or unwanted substances within the system. With access to a comprehensive spectral library, the software can pinpoint contaminants and trace them back to their sources, whether from materials, leaks, or process anomalies.

- Process Control | RGA data can be integrated into automated control systems. Setpoint relays can trigger valve actions at specific partial pressures, while analog outputs can feed into Programmable Logic Controllers for dynamic process adjustments, enabling closed-loop control.

Not All RGAs are Created Equal

INFICON has designed custom RGAs specifically for semiconductor applications, including metal PVD monitoring, improved lifetime in CVD/ALD and harsh environments, furnace and anneal monitoring, and selective etch monitoring. Our RGAs become even more powerful when integrated with our FabGuard® software, enabling smarter decisions by providing RGA data in the context of the manufacturing tool it supports.

Our Technical Note can help users understand the basics and key differentiators of RGAs and choose the best instrument for their unique needs and requirements.

Our RGAs

Gain advanced control and insight into ALD, CVD, and etch processes across multiple pressure ranges.

The advanced process expert for single-pressure ALD/CVD and etch.

The compact process expert for advanced process monitoring.