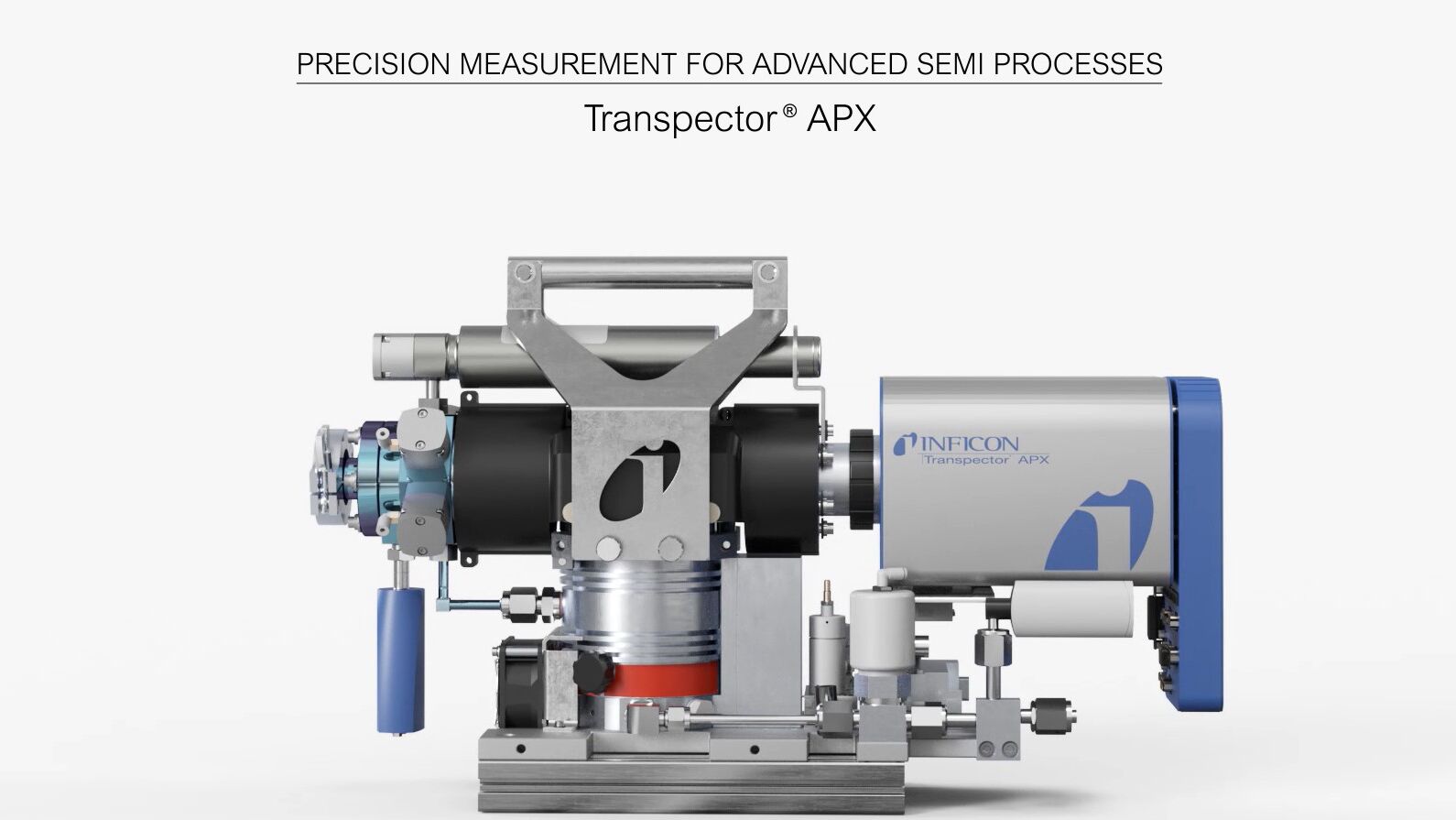

Transpector® APX Multi-Pressure

Gain instant insight, smarter control, and better yield.

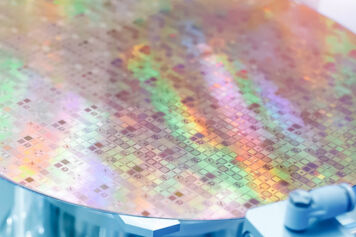

In advanced semiconductor manufacturing, every second and every molecule counts. Minute changes in process chemistry can directly affect film quality, uniformity, and yield. Most factories still struggle to see these changes in real time, especially under variable pressure and harsh-chemistry conditions. The ability to capture, analyze, and act on gas-phase data instantly is now essential not just for process control, but for smart, data-driven manufacturing.

Today’s advanced processes—whether ALD, CVD, PVD, or etch—demand real-time visibility, repeatability, and process control. Without it, manufacturers face:

- Unseen etch endpoints and residue buildup that cause wafer defects, yield loss, and costly rework

- Cross-chamber process mismatch, leading to inconsistent results and longer time-to-qualification for new tool sets and recipes

- Process drift and contamination from leaks, degraded chamber conditions, or contaminated process gases, driving up downtime and reducing yield

- Data silos between sensors and factory analytics, preventing engineers from correlating gas-phase signals with yield or equipment health in real time

Transpector APX Multi-Pressure is built for the smart factory of the future that allows you to see, understand, and control your critical processes.

Transform Your Critical Processes

See How Transpector APX Provides Real-Time Gas Analysis

Outcomes You Can Measure

Transform your factory’s critical processes by giving your engineers the visibility they need when it matters and where it matters. The Transpector APX Multi-Pressure isn’t just a gas analyzer; it’s the smart-manufacturing gateway to process excellence.

- Minimize scrap and unplanned tool downtime by capturing chemical signals at every phase.

- Faster ramp-up and recipe transfer thanks to consistent sensor data and calibration across tools.

- Reduce process drift and maintenance cost by proactively monitoring chemical and pressure conditions.

- Enhance data usage across the factory, which feeds analytics, FDC systems and predictive-maintenance platforms.

Advantages

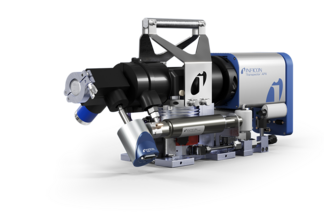

- Ultimate process monitoring: Over 550 data points per second for real-time insight into deposition and etch phases

- Harsh-chemistry ready: The HexBlock™ multi-inlet system with proprietary coating enables monitoring of corrosive and particulate-rich environments

- Space-efficient footprint: Up to 30% smaller footprint thanks to high-performance pumping, making integration into tight factory layouts easier

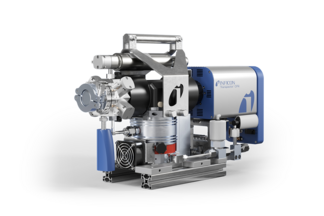

- Seamless tool-matching and analytics: Automated calibration and direct integration with factory analytics (via FabGuard®) ensure consistent chamber behavior and reliable cross-tool data

- Scalable integration across smart factories: The system supports layers of monitoring, diagnostics, and digital-twin readiness which aligns with Industry 4.0 and smart manufacturing initiatives

Specifications

| Total Pressure Range | 5E-7 to 1E-3 Torr (6.6E-7 to 1.3E-3 mbar) |

| Detection Limit | <10 ppb |

| Process Pressure Range | 1E-8 Torr to 1.2 atm (1.3E-8 mbar to 1.2 atm) |

| Sensitivity (Low Emission) | >4.0E-6 A/Torr (>3E-6 A/mbar) |

| Sensitivity (High Emission) | >2.0E-5 A/Torr (>1.5E-5 A/mbar) |

| Total Pressure Range | 5E-7 to 1E-3 Torr (6.6E-7 to 1.3E-3 mbar) |

| Detection Limit | <25 ppb |

| Process Pressure Range | 1E-8 Torr to 1.2 atm (1.3E-8 mbar to 1.2 atm) |

| Sensitivity (Low Emission) | >2.0E-6 A/Torr (>1.5E-6 A/mbar) |

| Sensitivity (High Emission) | >1.0E-5 A/Torr (>7.6E-6 A/mbar) |

| Total Pressure Range | 5E-7 to 1E-3 Torr (6.6E-7 to 1.3E-3 mbar) |

| Detection Limit | <50 ppb |

| Process Pressure Range | 1E-8 Torr to 1.2 atm (1.3E-8 mbar to 1.2 atm) |

| Sensitivity (Low Emission) | >1.0E-6 A/Torr (>7.6E-7 A/mbar) |

| Sensitivity (High Emission) | >5.0E-6 A/Torr (>3.8E-6 A/mbar) |

Consumables

| Part Number | Description |

| 969-800-G1S | APX CIS Tungsten Filament Kit GOLD |

| 969-800-G2S | APX CIS Coated Filament Kit GOLD |

| 969-801-G1S | APX CIS Tungsten Ion Source Kit GOLD |

| 969-801-G2S | APX CIS Tungsten Ion Source Kit with Anode Liner GOLD |

| 969-801-G3S | APX CIS Coated Ion Source Kit GOLD |

| 969-801-G4S | APX CIS Coated Ion Source Kit with Anode Liner GOLD |

| 961-707-G1 | Electron Multiplier Replacement Kit |

| 923-418-G2 | Replacement diaphragm kit for two-stage pump |