Ensuring Quality in Semiconductor Manufacturing with Advanced Leak Detection Solutions

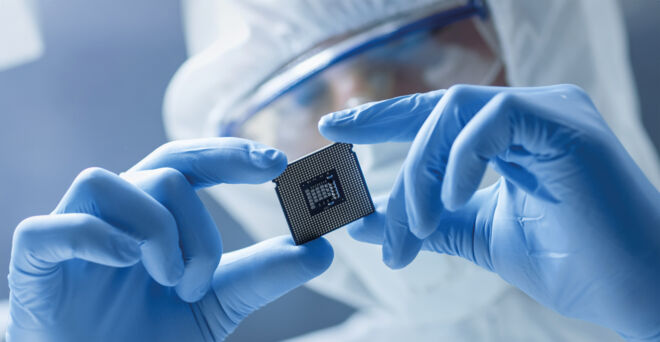

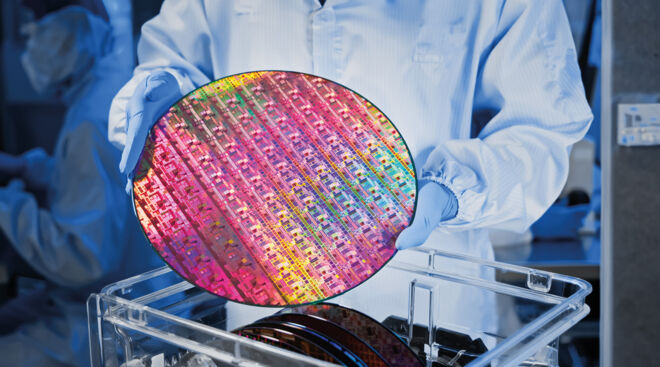

Semiconductors play a critical role in today's electronics industry. They are used in computers, smartphones, cars, household appliances, gaming systems, and medical equipment, and the increasing demand for chips requires precise manufacturing processes. Accurate leak detection plays a vital role in maintaining optimal conditions and to meet the challenges of the semiconductor industry. Here's how leak detection solutions from INFICON contribute to ensuring quality in semiconductor manufacturing:

- Maintaining Vacuum: precise leak detection ensures the integrity of vacuum conditions that are crucial for semiconductor processes. Identifying and fixing even the smallest leaks is essential to ensure the unique semiconductor properties.

- Preserving Cleanroom Conditions: leak detection with tracer gas is a non-contaminating method and aligns with cleanroom procedures. This prevents the introduction of particles and contaminants, upholding the stringent cleanliness standards of semiconductor cleanrooms.

- Locating Complex Leaks: advanced leak detection technologies, including the use of tracer gases, effectively locate leaks in complex semiconductor tool designs. This capability is vital for identifying and addressing leaks in diverse configurations of semiconductor equipment.

- Ensuring Sensitivity and Precision: precise, highly sensitive leak detection ensures the identification of even the smallest leaks. This level of accuracy is critical for maintaining the purity required in semiconductor manufacturing processes, preventing defects, and ensuring product quality.

- Materials Compatibility: leak detection solutions from INFICON are designed to be compatible with semiconductor materials. This is crucial to prevent adverse interactions that could potentially damage or alter the materials used in semiconductor fabrication.

- Detecting Leaks Fast for High Throughput: reliable leak detection systems offered by INFICON enable fastest and reliable results, contributing to high throughput in semiconductor manufacturing. Rapid identification and resolution of leaks minimize downtime, ensuring optimal production efficiency.

- Integration with Automated Systems: leak detection solutions from INFICON seamlessly integrate with automated systems, providing real-time feedback. This integration enables continuous monitoring, immediate response to leaks, and contributes to the overall equipment efficiency (OEE) of automated semiconductor manufacturing processes.

- Cost-Effective Solutions: INFICON is committed to developing cost-effective leak detection solutions that balance accuracy with cost considerations. In this way, costs in semiconductor manufacturing can be reduced without compromising reliability.

The offer from INFICON

INFICON offers leak detectors for both sniffing and vacuum leak testing, for use in semiconductor chips manufacturing, in production lines for solar cells, flat panel displays, glass and plastic foil coating, and vacuum systems in general.

UL6000 Fab Series is the flagship series of our UL mobile helium leak detector portfolio. It is designed for the bigger tool volumes in latest semiconductor Fabs and large coating tools used in solar cell manufacturing, flat panel display and sheet-to-sheet or roll-to-roll (web) coating. The unit delivers fastest response times in all measurement ranges and offers extremely short test times, making leak detection accurate, fast and easy. Its small footprint ensures best maneuverability and adequate working space in tighter tool space requirements of latest semiconductor fabs in an effort to use the costly cleanroom space most efficiently.

UL3000 Fab Series of mobile helium leak detectors specifically designed for the needs of leak checking of the majority of tools in latest semiconductor fabs. It features flexibility, mobility, fast start up, high sensitivity, fast and precise test results, and reliability. Its small footprint like the UL6000 Fab ensures best maneuverability and optimum working space in the tighter tool space requirements of modern fabs.

UL1000 Fab Series of mobile helium leak detectors is the renowned standard when it comes to economic helium vacuum leak testing in industrial or semiconductor environments in particular for smaller chamber volumes. The unit provides the best compromise between high performance, unparalleled robustness, and affordability.