Before & After: How SMART-Spray Transforms Your Leak Detection Process

From bulky equipment to wireless efficiency - discover a faster, safer, and more precise way to perform leak testing in semiconductor manufacturing

Leak testing in semiconductor manufacturing

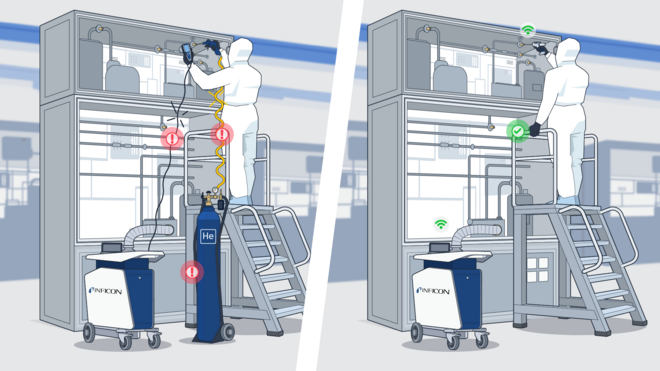

Leak detection is critical for ensuring quality control in semiconductor manufacturing - but it doesn’t have to be cumbersome. Traditional helium leak detection often means struggling with large cylinders, managing long hoses, and handling complex equipment. These challenges not only slow the leak checking process but also increase the risk of errors and safety hazards

Enter SMART-Spray from INFICON: This wireless, mobile helium spray gun changes the game - improving leak testing efficiency, speed, accuracy, and operator comfort. But how big is the difference? Let’s take a closer look at helium leak testing with and without SMART-Spray.

Leak Detection: Traditional vs. SMART-Spray

Before SMART-Spray:

🚫 Bulky helium cylinders that are hard to maneuver

🚫 Long, tangled hoses limiting mobility and increasing trip hazards

🚫 Manual spray adjustments prone to user error

🚫 Time-consuming setup for semiconductor leak detection and limited reach to all test points

🚫Remote Control required to read leak rate, where you spray

Operators often find themselves navigating tight spaces within complex and large equipment, all while trying to maintain precision - a challenging combination that leads to inefficiencies and potential safety risks.

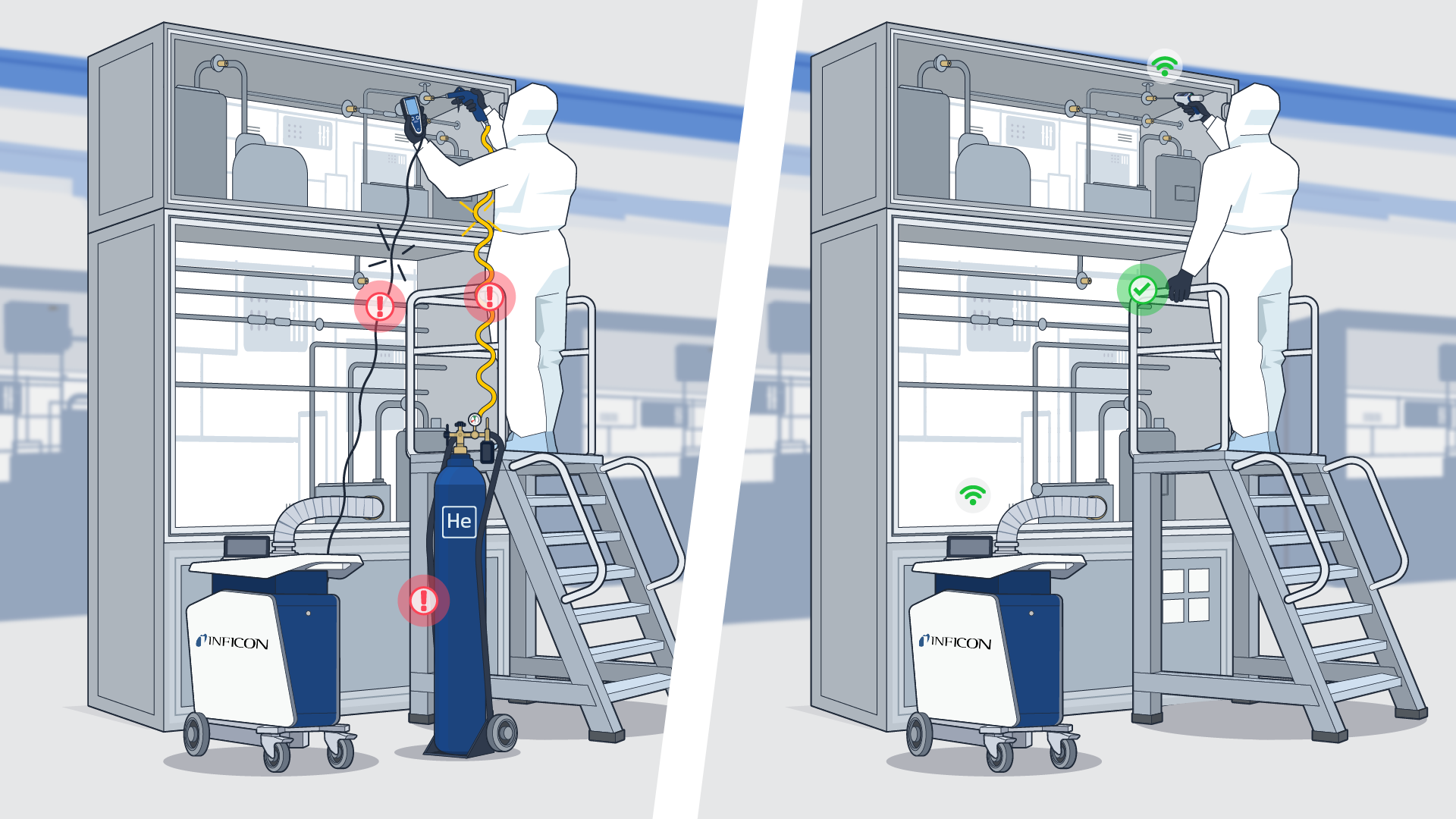

After SMART-Spray:

✅ Wireless and Mobile: Move freely without being tethered to hoses or cylinders

✅ Precision at Your Fingertips: Select from 4 different pre-adjusted helium flow settings directly on the device for consistent leak testing results

✅ Real-Time Data: The built-in display shows leak rates and device status at a glance

✅ Enhanced Safety: No hoses on the floor means fewer trip hazards

✅ More Space: Making the helium cylinder unnecessary means space gained for other operations

✅ Extended Use: Refillable, exchangeable Helium cartridges (HeliCan) and rechargeable/exchangeable batteries ensure seamless leak checking

By eliminating the physical and logistical challenges of traditional leak detection, SMART-Spray enables faster leak tests with greater accuracy. Operators can now access hard-to-reach areas without struggling with equipment, reducing both testing time and operator fatigue.

Move from cumbersome to convenient - experience the SMART-Spray difference today! Request a demo unit!

Contact our experts

Please fill in the adjacent form and one of our experts will contact you.

Why the Difference Matters:

In semiconductor manufacturing, where leak rate thresholds can be as stringent as 1 x 10⁻⁹ mbar·L/s, accuracy is non-negotiable. SMART-Spray ensures that operators can perform leak tests quickly and reliably - even in complex systems with numerous test points.

And it’s not just about speed - it’s about safety, efficiency, and ease of use. With fewer moving parts and a simplified leak checking process, SMART-Spray minimizes both physical strain and the risk of operational errors.

For more information visit our SMART-Spray product page.

Want to Stay Updated on Leak Detection?

Our newsletter offers regular updates on our latest products, applications, upcoming events, and other interesting news.

Connect with Us at Global Semiconductor Events!

We regularly attend major semiconductor exhibitions worldwide. Meet our experts, explore our latest innovations, and discuss your production challenges.