BES4000

Precise leak detection for battery modules and packs in modern battery production.

Next-Level Quality Control in Battery Pack Manufacturing

The BES4000 opens up the possibility of localizing electrolyte leaks.

Based on the principle of electrolyte sniffing, it detects smallest traces of electrolyte vapors escaping from defective cells. This makes it possible to quickly and reliably locate leaks directly on assembled battery packs and modules—without the need for chamber retesting.

During welding and handling, previously leak-tight cells can develop new micro-defects. The BES4000 identifies these leaks fast and with high accuracy, allowing targeted streamlined rework and thus saving significant cost. This saves time, materials, and resources while maintaining the highest safety and quality standards.

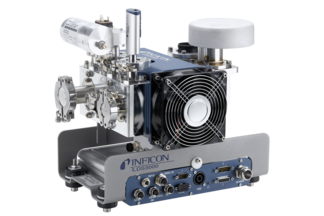

How It Works: Electrolyte Sniffing Technology

The BES4000 uses the electrolyte solvent itself—typically DMC or EMC—as the tracer gas. Escaping vapors are detected by a highly sensitive sensor system that reacts within one second. This enables operators to pinpoint the exact location of leaks, even within complex battery pack assemblies.

The Ideal Match for Cell Testing

Combined with the ELT series of electrolyte leak detectors, the BES4000 forms a closed feedback loop:

- ELT Vmax identifies which cells fail leak testing.

- BES4000 locates the precise leak position for process optimization.

Together, they ensure maximum reliability in every stage of battery production—from individual cell validation to full cell-to-pack testing.

Advantages at a Glance

- Finding smallest leaks thanks to high sensitivity

- Sensor only reacts to electrolyte vapors

- Preventing false alarms due to background with dual inlet

- High durability with long-life infrared sensor

- Quick response time for accurate pinpointing of leaks

- Fast recovery from gross leak for high uptime

- Calibrated leak rate traceable to national standards

Typical Applications

- Final Assembly Rework

Detect and localize defective cells inside battery modules and large battery packs. Faulty cells can be replaced quickly—increasing safety and longevity of the battery packs. - Cell Manufacturing Feedback

Locate microscopic leaks in electrolyte-failed cells, trace defects to their origin, and optimize process parameters for stable production. - Future-Ready Designs

Ideal for large-format packs and cell-to-pack architectures where full-chamber retesting is no longer feasible.

Specifications

| Smallest detectable leak rate | 0.5 g/a DMC (1 ppm) |

| Leak rate units | g/a, oz/yr, lb/yr, ppm |

| Detection sensor | IR technology |

| Response time | < 1 s |

| Interfaces | PROFIBUS, PROFINET, DeviceNet, EtherNet/IP, serial interfaces (RS232), digital I/Os |

| Dimensions (diameter, height) | 266 mm, 365 mm |

| Weight | 4.5 kg |

| Operating languages | German, English, Spanish, Korean, Chinese, Japanese |

Part Number

| 610-001 | BES4000 Electrolyte Sniffer Leak Detector |

| 560-310 | I/O 1000 module |

| 560-315 | BM1000 PROFIBUS module |

| 560-316 | BM1000 PROFINET IO module |

| 560-317 | BM1000 DeviceNet module |

| 560-318 | BM1000 Ethernet/IP module |

| 560-332 | Data Cable 2 m |

| 560-335 | Data Cable 5 m |

| 560-340 | Data Cable 10 m |

| 511-021 | Sniffer tip 100 mm |

| 511-024 | Sniffer tip 400 mm |

| 511-022 | Sniffer tip, 400 mm, pre-bent, 45° |

| 511-020 | Extension tip 400 mm |

| 511-029 | Extension for sniffer tip 500 mm, 45° angled |

| 511-040 | Extension for probe cable (4.8 m) |

| 511-027 | Filter holder for sniffer tip (20 pieces) |

| 611-001 | Sealing blocks (5 pieces) |

| 511-010 | Replacement for internal calibrated leak |