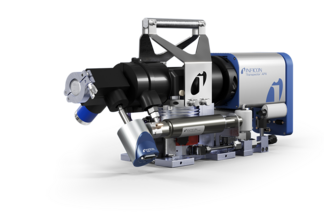

Hydrocarbon Detector (HCD)

Detect volatile organic compounds in industrial manufacturing settings.

Critical-Process Monitoring in Real Time

Take your manufacturing process control to the next level by detecting volatile organic compounds with the hydrocarbon detector from INFICON.

Our broadband, non-selective sensor monitors critical processes in harsh industrial manufacturing settings—including semiconductor, solar, pharmaceutical, or other vacuum-based process—and provides real-time detection of hydrocarbons and silicone oils with superior sensitivity.

Whether detecting photoresist contamination in semiconductor or pump oil contamination in freeze drying applications, the HCD sensor is a user-friendly and effective solution. It seamlessly integrates with existing systems or with INFICON FabGuard® software. The sensor is compatible with any chamber condition, and pumping system maintenance is not required.

Advantages

- Real-time monitoring

- Tailored sensor operation control and easy data interpretation

- Seamless tool integration and reliable interdiction through data acquisition

- Quick and easy sensor installation, minimized tool space occupation

- Low total cost of ownership, high return on investment

Specifications

| Operating Pressure Range | sub 1 Torr - 1 ATM |

| Limit of Detection | ppm to ppb based on operating pressure |

| Operating Temperature Range | -25C to 180C |

| Sensitivity (High Emission) | > 2E-5 Amps/Torr |

| Mounting Flange | Standard FK25; custom options available |

| Available Inputs/Outputs | 4-20mA, 0-10 V analog, Modbus TCP |

| Contamination Measurement by UV Photoionization | 10 / 10.6 eV Kr discharge |

Request More Information

Interested in learning how our HCD can improve your industrial processes?