New Approaches to Real-Time Metrology for Next-Generation Solar Cells

As solar manufacturers transition toward more advanced cell designs—including perovskite and complex thin‑film architectures—the need for precise, real-time process insight is essential. Subtle variations in layer thickness, material flux, or chamber environment can influence both device efficiency and long‑term durability. Traditional calibration routines and offline measurements struggle to keep pace with fast-changing deposition conditions.

In a recent article, INFICON Thin Film Sensor Specialist Sheldon Wayman highlights why fabs are increasingly turning to continuous in‑chamber monitoring to stabilize production and improve yield. Modern PVD and CVD coating processes can shift rapidly during a single run, making live feedback critical for maintaining uniformity and preventing contamination-related defects that result in lower efficiency.

The piece outlines several ways manufacturers can strengthen their metrology strategy, including:

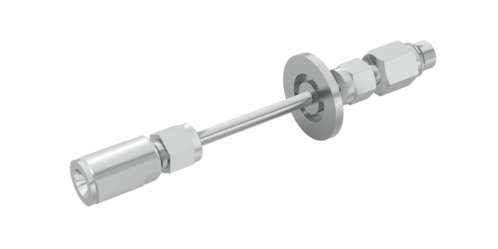

- Continuous thickness tracking using highly sensitive quartz crystal sensors

- Distributed sensing across the substrate plane to better understand evolving flux profiles

- Real-time detection of moisture, oxygen, and other reactive species that compromise device performance

- Monitoring of chamber-wall buildup to enable cleaning based on actual conditions rather than fixed schedules

Together, these methods give fabs a clearer picture of what is happening inside the chamber at every moment. When combined with intelligent software, this data supports closed-loop control, trend analysis, and predictive maintenance—tools that help reduce variability and lower operating costs.

As solar capacity expands and performance targets tighten, metrology that keeps pace with the process is becoming a strategic differentiator.

Click the button below to read the full article on Perovskite-Info and see how INFICON is helping solar manufacturers unlock higher efficiency and more reliable production.