Find Leaks Before They Stop Production

Precise Leak Localization in Battery Module and Pack Production.

Closing the Gap in Battery Leak Localization

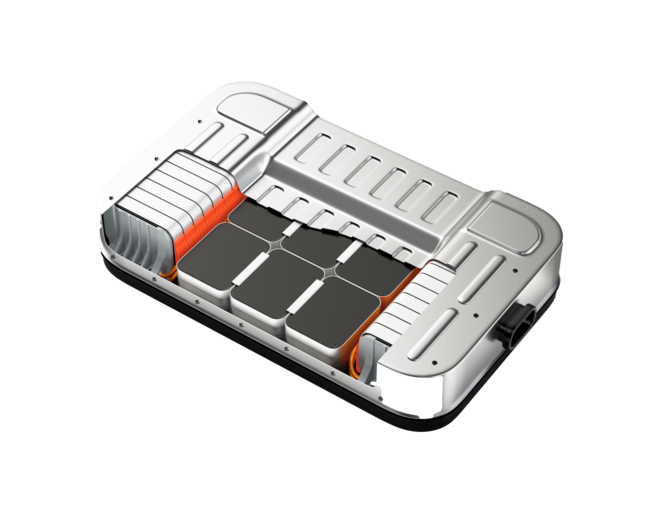

In modern battery manufacturing, maintaining tightness throughout all production steps is a growing challenge. During assembly and welding, even cells that have passed initial leak testing can develop new micro-defects. These very small electrolyte leaks may remain undetected by conventional methods, yet they can affect performance, safety, and service life.

As production scales up and designs become more compact, the need for precise and fast leak localization has increased across the industry. While end-of-line leak detection systems can identify defective modules or packs, finding the exact source of the leak has often required additional effort and time.

Addressing an Industry-Wide Challenge

To close this gap, INFICON developed the BES4000 Electrolyte Sniffer Leak Detector, a solution designed specifically for pinpointing electrolyte leaks in assembled battery modules and packs.

The system is based on Electrolyte Sniffing, a non-destructive method that detects vapors of electrolyte solvents such as DMC or EMC escaping from leaking cells. With a smallest detectable leak rate of 0.5 g/a (1 ppm) and a response time below one second, BES4000 enables precise pinpointing directly on the production line.

This targeted approach supports fast rework instead of scrapping, reduces material loss, and shortens production cycles.

Perfect Match with ELT Vmax

BES4000 works seamlessly with the INFICON ELT Vmax Electrolyte Leak Detector. While ELT Vmax identifies if cells fail leak testing, BES4000 pinpoints the exact location of the leak. Together, both systems form a consistent workflow from detection to localization and provide valuable insight into process stability and long-term quality trends.

Ready for Modern Production Lines

Compact, robust, and integration-ready, BES4000 can be used in both final assembly rework and cell manufacturing diagnostics.

It supports modern fieldbus communication and is ready for operation within 30 seconds, making it suitable for high-throughput production environments.

Key Advantages

- Non-destructive electrolyte leak detection (DMC, EMC) for battery packs and modules

- Leak localization down to the cell level

- Enables targeted rework and process optimization

- Perfect complement to ELT Vmax

- Designed for modern and future battery architectures

A Step Forward in Battery Quality Control

With the launch of BES4000, INFICON expands its portfolio for advanced battery leak testing. The combination of high sensitivity, short response times, and seamless integration helps manufacturers meet rising quality standards while reducing costs and environmental impact.

Connect with Us at Global Mobility and Automotive Events!

We frequently attend major battery and automotive exhibitions worldwide. Meet our experts, explore our latest innovations, and discuss your production challenges.