Real-Time Residual Gas Analysis for Enhanced Etch Process Control

Gain insight to improve etch precision, selectivity, and process stability at atomic-scale dimensions.

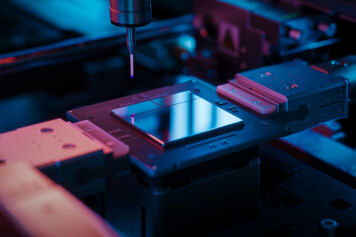

As semiconductor devices scale below 3 nm, process precision has become a dominant constraint on yield and device reliability. Etching is among the most demanding fabrication steps, requiring the removal of targeted material layers while preserving adjacent structures that are only a few atoms thick. Variations in chamber chemistry (even on short timescales) can alter etch profiles, selectivity ratios, or surface morphology.

Recent developments in in situ residual gas analysis (RGA) have introduced a more detailed view of these dynamics. RGAs employ quadrupole mass spectrometry to continuously monitor the chemical composition of process gases, enabling the detection of volatile byproducts and reaction intermediates in real time. This data allows for a more direct link between process chemistry and etch outcomes, advancing both process understanding and control strategies.

Studies and industrial trials have demonstrated that RGAs can identify subtle changes in process chemistry that precede measurable deviations in etch performance. For example, variations in the concentrations of halogenated byproducts or hydrocarbon fragments can signal chamber drift, material loading effects, or changes in surface reactions. By monitoring these trends, process engineers can correlate gas-phase behavior with etch depth, selectivity, and uniformity, ultimately refining recipe stability and identifying potential excursions.

In current implementations, such as the INFICON Transpector® APX, the sensor is configured to operate directly within the etch environment, where it continuously samples exhaust gas composition. The instrument’s design, which includes temperature-controlled components and corrosion-resistant coatings, enables sustained operation in reactive process environments.

Beyond real-time monitoring, RGA data supports a broader transition toward data-driven process optimization. When integrated with statistical process control or machine learning algorithms, gas composition signals can function as predictive indicators for endpoint accuracy and equipment health. In this way, RGAs contribute not only to process diagnostics but also to the development of adaptive control frameworks supporting autonomous manufacturing systems.

In summary, residual gas analysis represents a maturing diagnostic and emerging process control tool for advanced semiconductor etch processes. By linking chemical insight with data analytics, it offers a quantitative foundation for improving selectivity, reproducibility, and tool stability in next-generation device manufacturing.

Gain More Insights from INFICON

Advanced packaging not only keeps chips smaller and more efficient but allows for more powerful, versatile systems.

As technology devices get smaller and chips become denser, manufacturers need ways to continue increasing performance while minimizing power consumption and footprint.

The next generation of manufacturing will be defined by autonomy and real-time optimization.