Porter® CDG020D

The Harmony of Accuracy and Engineering Excellence

Revolutionize your vacuum gauge experience with us!

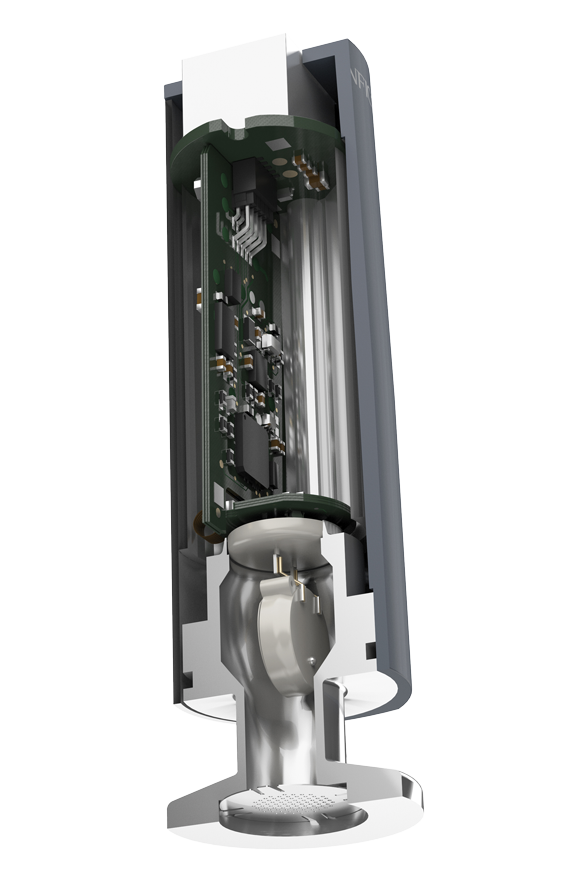

The INFICON Porter® CDG020D Capacitance Diaphragm Gauge is a high quality, cost effective, gas type independent absolute pressure sensor.

The INFICON Porter CDG020D Capacitance Diaphragm Pressure Gauge, with its remarkable range stability and unmatched long-term performance, is the pinnacle of pressure measurement technology. The gas-independent, absolute pressure gauge is simple to implement and requires minimal upkeep.

Introduction to Porter Gauge

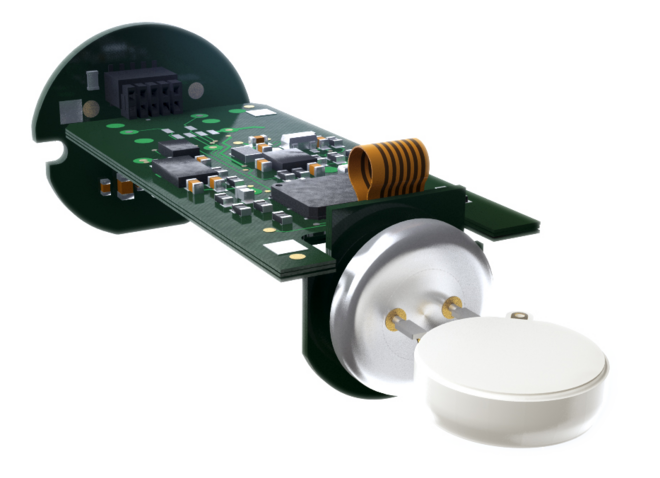

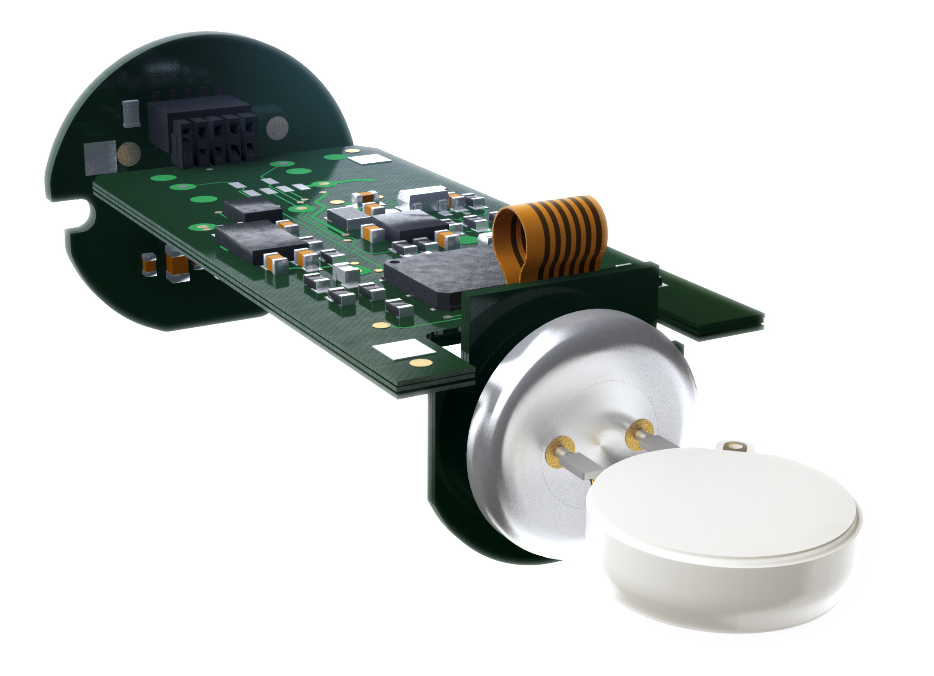

Our commitment to quality and precision is evident in the Porter CDG020D gauge, a device that can increase efficiency and safety in a variety of processes. Building on this commitment, the Porter CDG020D gauge features a ceramic sensor cell, ensuring its performance is gas type independent and reliably consistent across diverse applications.

From vacuum coating to vacuum monitoring, this sensor provides reliable data essential for maintaining production standards. Its ability to measure different gas types without calibration makes it a valuable tool for analytical and chemical vacuum process applications where accuracy and adaptability are critical.

The Latest Porter Technology

The state-of-the-art technology of the Porter CDG020D is evident not only in its rugged sensor technology and is also suitable in different applications. In the food and packaging industry, the sensor's precise pressure measurement allows for improved control during modified atmosphere packaging, increasing product shelf life and safety.

The advanced alumina ceramic sensor ensures high performance, which is reliable in vacuum applications as in ovens and sterilization processes.

Special Qualities and Advantages

Porter CDG020D differs from other pressure gauges in its compact size and ease of integration, making it attractive for complex machine arrangements. Any mounting orientation allows for versatile use in the tight spaces. In addition, the unit's digital signal processing supports fast and accurate pressure measurement, which is critical for maintaining process quality.

These unique features make Porter CDG020D an indispensable component in modern industrial metrology, where precision, flexibility and long-term stability can make all the difference. With its rugged design and integration of state-of-the-art sensor technology, the Porter sensor represents the future of pressure measurement technology, adapted to the diverse requirements of industrial applications.

Benefits

- Excellent span stability – gas type independent

- Alumina sensor

- Compact, smallest size in it's class

- Easy integration, any mounting orientation

- Digital signal processing

- Maintenance free

Typical applications

- Vacuum coating

- Vacuum monitoring

- Sterilization

- Food & packaging

- Vacuum oven, puller

- Analytical

- Chemical vacuum processes

Specifications

| Accuracy | % of reading | 0.5 or 1 |

| Resolution | percent FS | 0.05 |

| Output signal (analog) | V (dc) | 0 … +10 |

| Response time (1) | ms | 100 |

| Materials exposed to vacuum | Aluminum oxide ceramic (AI2O3), stainless steel 1.4404 (AISI 316L) |

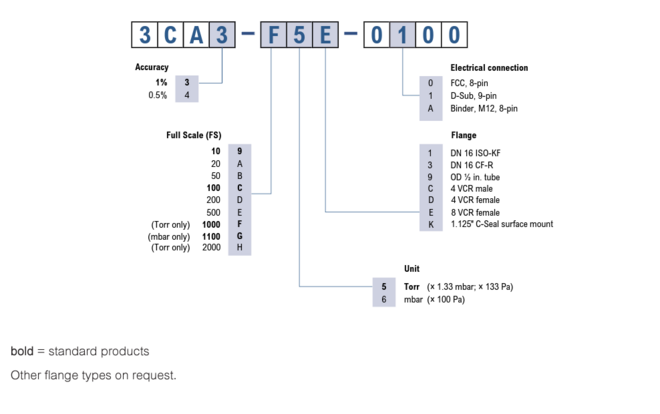

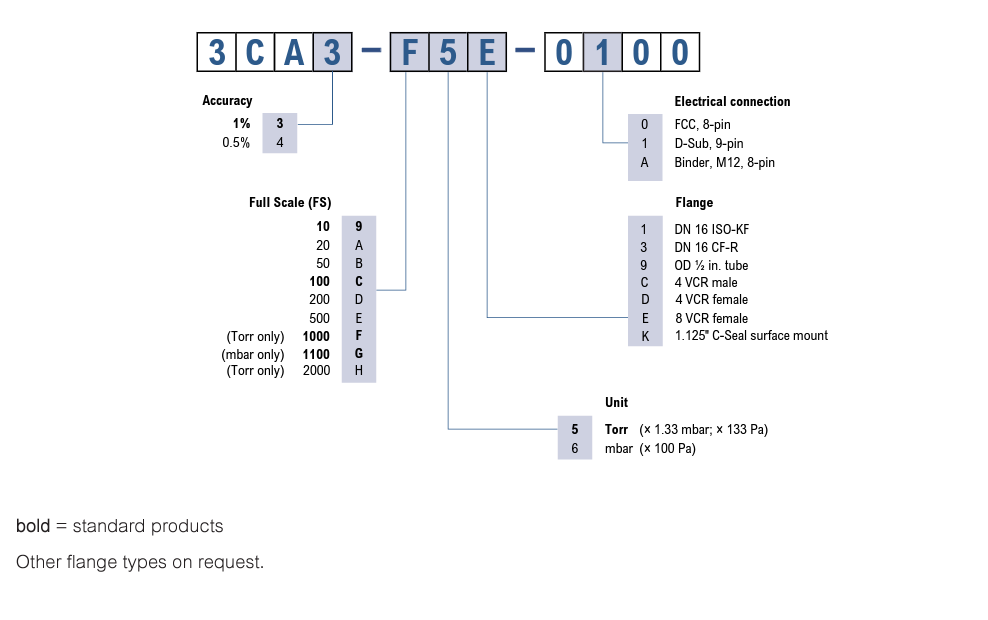

Part Number