BAG05x

Bayard-Alpert passive gauge heads for VGC083

Revolutionize your vacuum gauge experience with us!

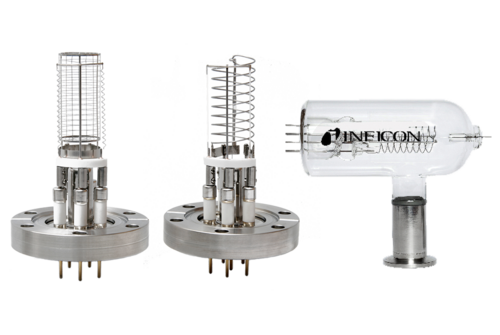

The hot cathode ionization passive vacuum gauge heads BAG05x are nude (BAG050, BAG051) or glass tube (BAG052, BAG053) Bayard-Alpert sensors designed for use with the Vacuum Gauge Controller VGC083A/B.

- BAG050 is an electron bombardment (EB) degas nude ionization vacuum gauge capable of UHV pressure measurement as low as 2×10-11 mbar.

- BAG051 is a resistive (I2R) degas nude ionization vacuum gauge capable of pressure measurement as low as 5×10-10 mbar.

- BAG052 and BAG053 are resistive degas (I2R) glass enclosed ionization vacuum gauges capable of pressure measurement as low as 5×10-10 mbar.

Ytrium oxide coated iridium filaments are offered for general vacuum applications where air and inert gases, such as N2 and argon, are present. Tungsten filaments are offered for specific applications where yttrium oxide coated iridium filaments are not compatible. The BAG05x gauge heads are designed for low outgassing vacuum systems and can be baked up to extreme high temperature (450 °C). BAG05x gauges are largely compatible and may be operated with other user-selected compatible vacuum gauge controllers.

Advantages

- Long standing, reliable and proven gauge head design

- Drop-in replacement for most nude hot ion gauge heads

- Wide range of emission currents (100 μA to 10 mA)

- Available with single/dual yttrium oxide coated iridium and dual tungsten filament cathode assemblies

- Degas: all models can be degassed using in electron bombardment (EB), BAG051, BAG052 and BAG053 can also be degassed using resistive degas (I2R)

Typical applications

- Industrial or R&D applications requiring precise vacuum measurement in the high/ultra-high vacuum range and high temperature bake-out

Operating Units

- Vacuum Gauge Controller VGC083A/B

Specifications

| Measurement principle | Bayard-Alpert, hot cathode ionization |

| Gauge type | Electron bombardment (EB) degas nude gauge |

| Measurement range | 2.7×10-11 ... 1.3×10-3 mbar |

| Accuracy (N2) | ±20 % of reading |

| Repeatability (N2) | ±5 % of reading |

| Feedthrough | Al2O3 ceramic |

| Bake-out temperature | ≤450°C |

| Materials exposed to vacuum | Stainless steel, Al2O3, W, Y2O3 |

| Features | Available with following filament options: |

| Measurement principle | Bayard-Alpert, hot cathode ionization |

| Gauge type | Resistive (I2R) degas nude gauge |

| Measurement range | 5.3×10-10 ...1.3×10-3 mbar |

| Accuracy (N2) | ±20 % of reading |

| Repeatability (N2) | ±5 % of reading |

| Feedthrough | Al2O3 ceramic |

| Bake-out temperature | ≤450°C |

| Materials exposed to vacuum | Stainless steel, Al2O3, W, Y2O3 |

| Features | Available with following filament options: |

| Measurement principle | Bayard-Alpert, hot cathode ionization |

| Gauge type | Resistive (I2R) degas glass enclosed gauge |

| Measurement range | 5.3×10-10 ... 1.3×10-3 mbar |

| Accuracy (N2) | ±20 % of reading |

| Repeatability (N2) | ±5 % of reading |

| Feedthrough | glass |

| Bake-out temperature | ≤450°C |

| Materials exposed to vacuum | Glass, Al2O3, W, Y2O3 |

| Features | Single Y2O3 coated iridium (Ir) filament |

| Measurement principle | Bayard-Alpert, hot cathode ionization |

| Gauge type | Resistive (I2R) degas glass enclosed gauge |

| Measurement range | 5.3×10-10 ... 1.3×10-3 mbar |

| Accuracy (N2) | ±15 % of reading |

| Repeatability (N2) | ±5 % of reading |

| Feedthrough | glass |

| Bake-out temperature | ≤450°C |

| Materials exposed to vacuum | Glass, Al2O3, W, Y2O3 |

| Features | Available with following filament options: - Dual, Y2O3 coated iridium (Ir) - Dual, tungsten (W) |

Part Number

| BAG050 | |

| 399-720 | BA nude EB-degas, DN40CF, dual iridium filament (Ir) |

| 399-721 | BA nude EB-degas, DN40CF, dual tungsten filament (W) |

| 399-730 | Spare dual iridium filament (Ir) |

| 399-731 | Spare dual tungsten filament (W) |

| BAG051 | |

| 399-725 | BA nude I2R, DN40CF, single iridium filament (Ir) |

| 399-726 | BA nude I2R, DN40CF, dual iridium filament (Ir) |

| 399-727 | BA nude I2R, DN40CF, dual tungsten filament (W) |

| 399-735 | Spare V-iridium filament (Ir) |

| 399-736 | Spare dual iridium filament (Ir) |

| 399-737 | Spare dual tungsten filament (W) |

| BAG052 | |

| 399-740 | BA glass I2R, ¾’’ Kovar metal inlet port, single iridium filament (Ir) |

| 399-741 | BA glass I2R, 1’’ Kovar metal inlet port, single iridium filament (Ir) |

| 399-742 | BA glass I2R, ¾’’ glass inlet port, single iridium filament (Ir) |

| 399-743 | BA glass I2R, 1’’ glass inlet port, single iridium filament (Ir) |

| 399-744 | BA glass I2R, DN 25 ISO-KF, single iridium filament (Ir) |

| 399-745 | BA glass I2R, DN 40 ISO-KF, single iridium filament (Ir) |

| 399-746 | BA glass I2R, DN 16 ISO-CF, single iridium filament (Ir) |

| 399-747 | BA glass I2R, DN 40 ISO-CF, single iridium filament (Ir) |

| BAG053 | |

| 399-750 | BA glass I2R, ¾’’ Kovar metal inlet port, dual tungsten filament (W) |

| 399-751 | BA glass I2R, 1’’ Kovar metal inlet port, dual tungsten filament (W) |

| 399-752 | BA glass I2R, ¾’’ glass inlet port, dual tungsten filament (W) |

| 399-753 | BA glass I2R, 1’’ glass inlet port, dual tungsten filament (W) |

| 399-754 | BA glass I2R, DN 25 ISO-KF, dual tungsten filament (W) |

| 399-755 | BA glass I2R, DN 40 ISO-KF, dual tungsten filament (W) |

| 399-756 | BA glass I2R, DN 16 ISO-CF, dual tungsten filament (W) |

| 399-757 | BA glass I2R, DN 40 ISO-CF, dual tungsten filament (W) |

| Cables to VGC083A | |

| to BAG050 50 °C | |

| 399-780 | 3 m (9 ft) |

| 399-781 | 8 m (25 ft) |

| 399-782 | 15 m (50 ft) |

| to BAG050 200°C | |

| 399-770 | 3 m (9 ft) |

| 399-771 | 8 m (25 ft) |

| 399-772 | 15 m (50 ft) |

| 399-779 | Touch protection cover for cables 200 °C (BAG050, BAG051) |

| Cables to VGC083B | |

| to BAG051 50°C | |

| 399-780 | 3 m (9 ft) |

| 399-781 | 8 m (25 ft) |

| 399-782 | 15 m (50 ft) |

| to BAG051 200°C | |

| 399-770 | 3 m (9 ft) |

| 399-771 | 8 m (25 ft) |

| 399-772 | 15 m (50 ft) |

| 399-779 | Touch protection cover for cables 200 °C (BAG050, BAG051) |

| to BAG052/053 50°C | |

| 399-790 | 3 m (9 ft) |

| 399-791 | 8 m (25 ft) |

| 399-792 | 15 m (50 ft) |