FabGuard®

ASG-100

Fail-to-Safe Switch

Safely realize benefits from subfab and process data integration.

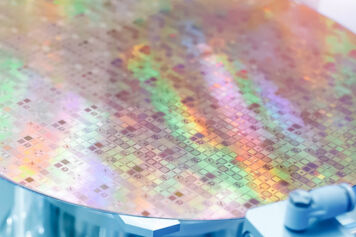

In the demanding world of semiconductor manufacturing, SEMI S2 guidelines set the standard for ensuring equipment meets critical environmental, health, and safety requirements. Compliance not only helps keep people, equipment, and facilities safe, it ensures fabs can operate with confidence.

The FabGuard® ASG-100 Fail-to-Safe Switch seamlessly integrates with INFICON FabGuard software so fabs can safely control subfab systems and equipment remotely with a SEMI S2 certified solution. This fail-to-safe remote switch is designed to keep systems operational without releasing unregulated harmful gases and chemicals into the environment (e.g., CO, CO2, NOx), even if the FabGuard control software loses communication with the target equipment.

With ASG-100, fabs can improve process control and gain a clear view of potential impacts. With this information, users can understand when to turn off their subfab systems based on process tool state, thereby reducing the expensive consumption of greenhouse gases. Users who pair ASG-100 with FabGuard Facilities Monitor to safely control abatement systems have saved approximately 50% in fuel by toggling the abatement based on demand.

Advantages

- Maintain SEMI S2 compliance

- Optimize tool uptime

- Prevent release of harmful gases and chemicals

- Improve yield

- Gain a uniform subfab control solution across all equipment types and platforms

- Significantly reduce fuel and oxidizer consumption

Industry Standard Compliance

The FabGuard ASG-100 Fail-to-Safe Switch has been certified to comply with CE and the following standards:

- ISO 12100

- EN ISO 13849-1

- EN ISO 1349-2

- IEC 61010-1

- SEMI S2-0821

- SEMI S10-1117

Semi S2 certification is only valid when paired with FabGuard Controller.

Features

- Remote-controlled subfab systems

- Agnostic platform

- Seamless integration with FabGuard software

- Automatic fail-to-safe mode

- Various mounting options

- Easily visualized alarms with LEDs

- Timestamp of last alarm occurrence

- Reset button for manual reset after an alarm

Schedule a Demo with Us

Contact us to learn how to maintain SEMI S2 compliance during process control with a free FabGuard demo.