EcoBoost by INFICON: Faster, Smarter Leak Testing with Helium and Hydrogen

VES relies on dynamic background compensation for efficiency and reliability

Vacuum Engineering Services (VES) in Manchester, UK, has been a trusted name in industrial leak testing for more than 30 years. As a long-standing partner of INFICON, VES played a key role in beta testing EcoBoost, a breakthrough firmware feature of the LDS3000 leak detector.

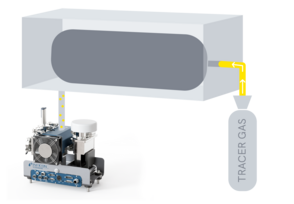

EcoBoost dynamically forecasts and compensates the test gas background during measurement. The result: leak tests become faster, more efficient, and more economical, whether using helium or hydrogen as tracer gas.

Three Decades of Leak Testing Expertise

Founded in 1994, VES has delivered more than 1,600 leak testing systems worldwide, serving industries from automotive to energy and electronics. Its portfolio covers:

- Design and manufacturing of test systems

- Global service and support

- Training, consultancy, and retrofits

- In-house and on-site leak detection services

- Helium recovery and purification solutions

With technical centers in the USA, Mexico, UK, Czech Republic, and China, VES combines global reach with deep engineering expertise.

Why Dynamic Background Compensation Matters

In production lines, leak testing must balance speed, cost, and quality. Conventional static background compensation acts like a tare button on a scale: once chamber evacuation is complete, the residual background is measured once. But this approach has two drawbacks:

- It requires waiting until evacuation stabilizes.

- If the measurement is started too early, small leaks may remain invisible, large leaks may be measured inaccurately.

EcoBoost solves these issues by dynamically predicting the background gas curve and subtracting it from the live measurement. This allows for:

- Faster testing cycles

- Reliable detection of smaller leaks

- Reduced helium consumption

Breakthrough for Hydrogen Testing

Hydrogen has clear cost advantages, but until now it was difficult to use in vacuum chambers due to higher background levels. INFICON adapted EcoBoost to continuously compensate for hydrogen backgrounds, making hydrogen leak testing practical for the first time.

Andrea Whittle from VES, tested EcoBoost in hydrogen composite tank applications for fuel cell vehicles. Her conclusion:

Faster Helium Testing in Automotive Applications

VES also applies EcoBoost in helium leak testing of motorcycle and agricultural fuel tanks. With multiple tank variants on the same production line, EcoBoost keeps production moving—even when a leak is detected. Instead of waiting for the chamber to clear, the LDS3000 compensates automatically, maintaining testing rhythm and avoiding downtime.

Reducing Helium Concentration Without Slowing Down

EcoBoost also enables testing with lower helium concentrations. In HVAC/R applications, customers already request testing with only 10% helium. Normally, this would mean longer evacuation times and slower cycles. With EcoBoost, testing speed is maintained while helium consumption is reduced.

Clear Advantages for Industry

For VES and its customers, EcoBoost offers only benefits:

- Faster testing cycles

- More consistent and reliable results

- Lower tracer gas consumption

- Practical hydrogen testing for the first time

As Whittle concludes:

With EcoBoost, INFICON and VES are pushing the boundaries of industrial leak testing, delivering measurable value across automotive, hydrogen, refrigeration, and beyond.

Also discover how EcoBoost can make your leak testing faster and more economical, while using helium as a tracer gas—try the EcoBoost Helium Savings Calculator, watch our on-demand webinar or read more about EcoBoost in our latest news article.

Download Free E-Book

Connect with Us at Global Mobility and Automotive Events!

We frequently attend major battery and automotive exhibitions worldwide. Meet our experts, explore our latest innovations, and discuss your production challenges.