Introducing EcoBoost

Enhanced Efficiency in Leak Testing with LDS3000

After two years of rigorous customer testing yielding highly favorable results, INFICON is proud to announce the formal release of the EcoBoost feature (formerly known as I·Zero 3.0) in the LDS3000 Helium and Hydrogen Leak Detector. With the latest software version 3.16, EcoBoost transitions from beta status to full release status, offering enhanced capabilities to users.

What is EcoBoost (formerly I·Zero 3.0)?

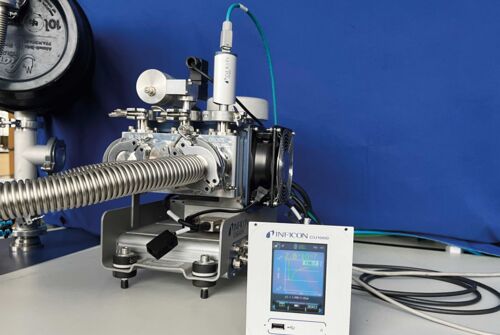

EcoBoost builds on the excellent repeatability and linearity of the LDS3000 to accurately predict the decreasing helium background in a vacuum leak testing system. The helium background forecast is taken into account to create a higher effective sensitivity of the helium leak detection system in industrial applications. Thus, small helium leak rates can be detected on an elevated and still decreasing background. Larger helium leak rates will be measured more accurately and, smaller leak rates will be detected with high reliability with the EcoBoost feature.

What are the benefits of using EcoBoost?

Faster Cycle Times:

With EcoBoost, measurements can start much earlier while the helium background is still decreasing, reducing cycle times and increasing throughput without compromising accuracy.

Lower Helium Consumption:

The higher effective sensitivity of EcoBoost enables the use of lower helium concentrations while still reliably detecting small leaks, resulting in cost savings on helium consumption.

Higher Uptime:

EcoBoost ensures the leak testing process remains operational, even after detecting gross leaks in the previous testing cycle. Additionally, elevated background concentrations of helium, often referred to as helium contamination, no longer impede or slow down production processes.

Success story for EcoBoost

One of the early adopters of the EcoBoost feature was the German system integrator Worthmann Maschinenbau who implemented EcoBoost in a system designed for testing fuel cell bipolar plates. This successful implementation underscores the effectiveness and versatility of EcoBoost in real-world industrial applications.

With the introduction of EcoBoost, INFICON reaffirms its commitment to delivering cutting-edge solutions that redefine efficiency and productivity standards in leak testing procedures. Leveraging advanced technology and customer-centric innovation, EcoBoost sets a new benchmark for excellence in leak detection across diverse industrial applications.

If you are interested in even more information just register to our online Webinar on 21 March 2024

EcoBoost: New Software for Faster Cycle Times and Cost Savings | INFICON