Electrolyte Leak Testing Redefined: 10× More Sensitivity for Li-Ion, Na-Ion, and Semi-Solid-State Battery Cells

Faster, More Sensitive, and Future-Proof Leak Detection with the INFICON ELT Vmax 2.0

The next generation of electrolyte leak detection is here. INFICON’s updated ELT Vmax system enables industrial battery manufacturers to detect even the smallest leaks in lithium-ion, sodium-ion, and gel-based semi-solid-state battery cells—with a tenfold increase in sensitivity and up to 30% faster test cycles.

With a new lower detection limit of 5 × 10⁻⁸ mbar∙L/s, the ELT Vmax supports even faster high-speed inline testing while also unlocking new applications: testing in larger vacuum chambers, module-level inspections, and compatibility with next-generation cell designs.

High-Sensitivity Electrolyte Leak Testing, What It Means for Battery Manufacturing

Higher Test Sensitivity

Thanks to a newly developed firmware and new, optimized signal processing algorithm, the ELT Vmax detects electrolyte solvent molecules at unprecedented low leak rates. This breakthrough enables:

- Accurate detection of micro-leaks, even in complex or large test setups

- Testing of entire modules, not just individual cells

- Detection of gel electrolyte leaks in semi-solid-state cells—critical for tomorrow’s high-energy-density batteries

Up to 30% Faster Test Cycles

The ELT Vmax is built for high-throughput environments:

- Compact internal volumes and improved signal evaluation algorithms result in shorter response times. Fastest cycles can be as low as 7–8 seconds

- Optimized inline operation using multiple vacuum chambers allows for highest utilization of the leak detector

The Only Solution for Leak Testing After Electrolyte Filling

Once lithium-ion or sodium-ion cells are filled with liquid electrolyte, traditional methods like helium bombing fail. The reason: Helium will always rise to the top and will not find its way through microleaks, rendering the test invalid.

INFICON’s patented solution turns this challenge into an opportunity by using the electrolyte solvent itself as the tracer gas, saving a huge amount in helium costs. In a vacuum, it evaporates and is immediately detectable via mass spectrometry. This method is now widely adopted in battery production lines worldwide.

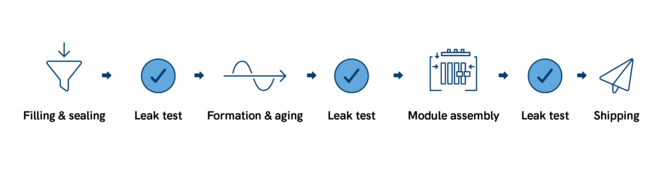

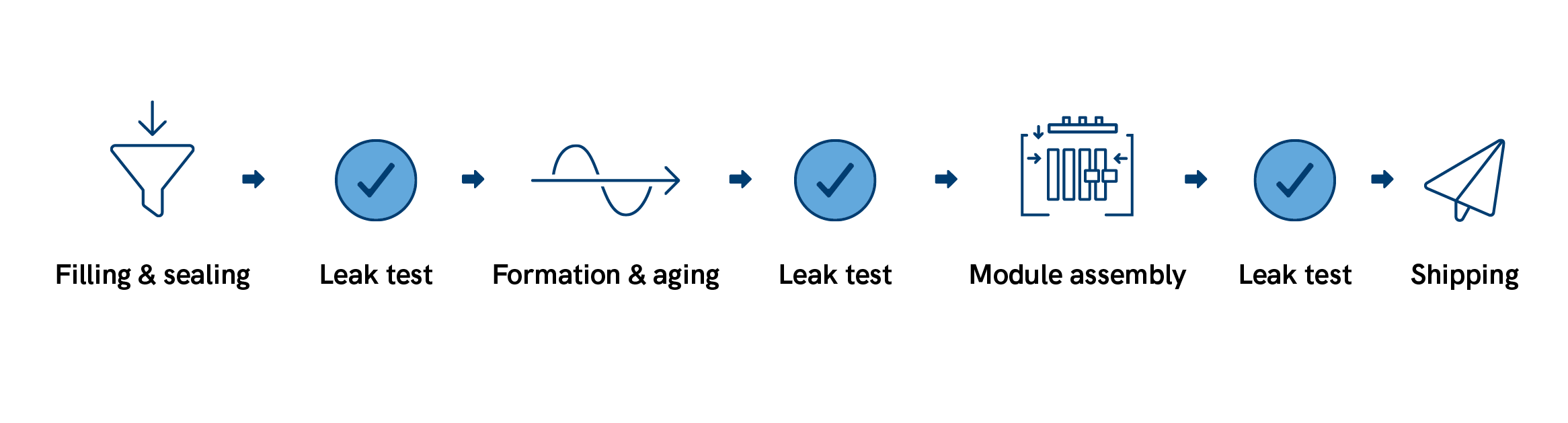

New Capabilities: From Individual Cells to Entire Battery Modules

The ELT Vmax is the ideal solution for comprehensive leak testing at every step of your manufacturing process. With its advanced technology and versatility, the ELT Vmax offers precise and reliable performance that can be utilized from the first to the last phase of production.

Testing Battery Modules after Assembly and Welding

During module assembly, battery cells are welded together using busbars. This process can unintentionally damage the cell housing, especially in pouch formats. The ELT Vmax can now detect this damage after module assembly—and only the ELT Vmax can do so.

Ready for Semi-Solid-State Cells

Semi-solid-state batteries promise energy densities of up to 500 Wh/kg and reduced overheating during fast charging. These cells use gel-like electrolytes that escape more slowly during testing, but the high sensitivity of ELT Vmax still ensures reliable and fast detection of critical leaks.

This makes the ELT Vmax a future-proof investment, ready for the next generation of EV batteries.

Engineered for Inline Testing in High Speed Production

The ELT Vmax was developed from the start to meet the demands of modern battery manufacturing:

- Integrates into automated leak test systems

- Supports multiple vacuum chambers for high-efficiency testing

- Compact 19-inch rack-mountable design

- Configurable batch testing for optimal throughput and yield

- Automated calibration and gross leak protection

- Modern fieldbus interfaces for seamless communication and data exchange

A Leap Forward in Battery Quality Assurance

The enhanced ELT Vmax software represents a quantitative and qualitative leap for leak testing in the battery industry. With 10× better sensitivity, up to 30% faster cycle times, and new capabilities including module-level testing, it delivers:

- Higher throughput

- Lower cost per test

- Reliable results across all major cell formats and different cell chemistries

- Future-proofing for evolving battery technologies

INFICON’s direct electrolyte leak detection is now more powerful, versatile, and indispensable than ever.

Download Free Whitepaper

Want to learn more?

Watch our free online webinar about the advantages of ELT Vmax in battery production.

Connect with Us at Global Mobility and Automotive Events!

We frequently attend major battery and automotive exhibitions worldwide. Meet our experts, explore our latest innovations, and discuss your production challenges.