SmartFDC®

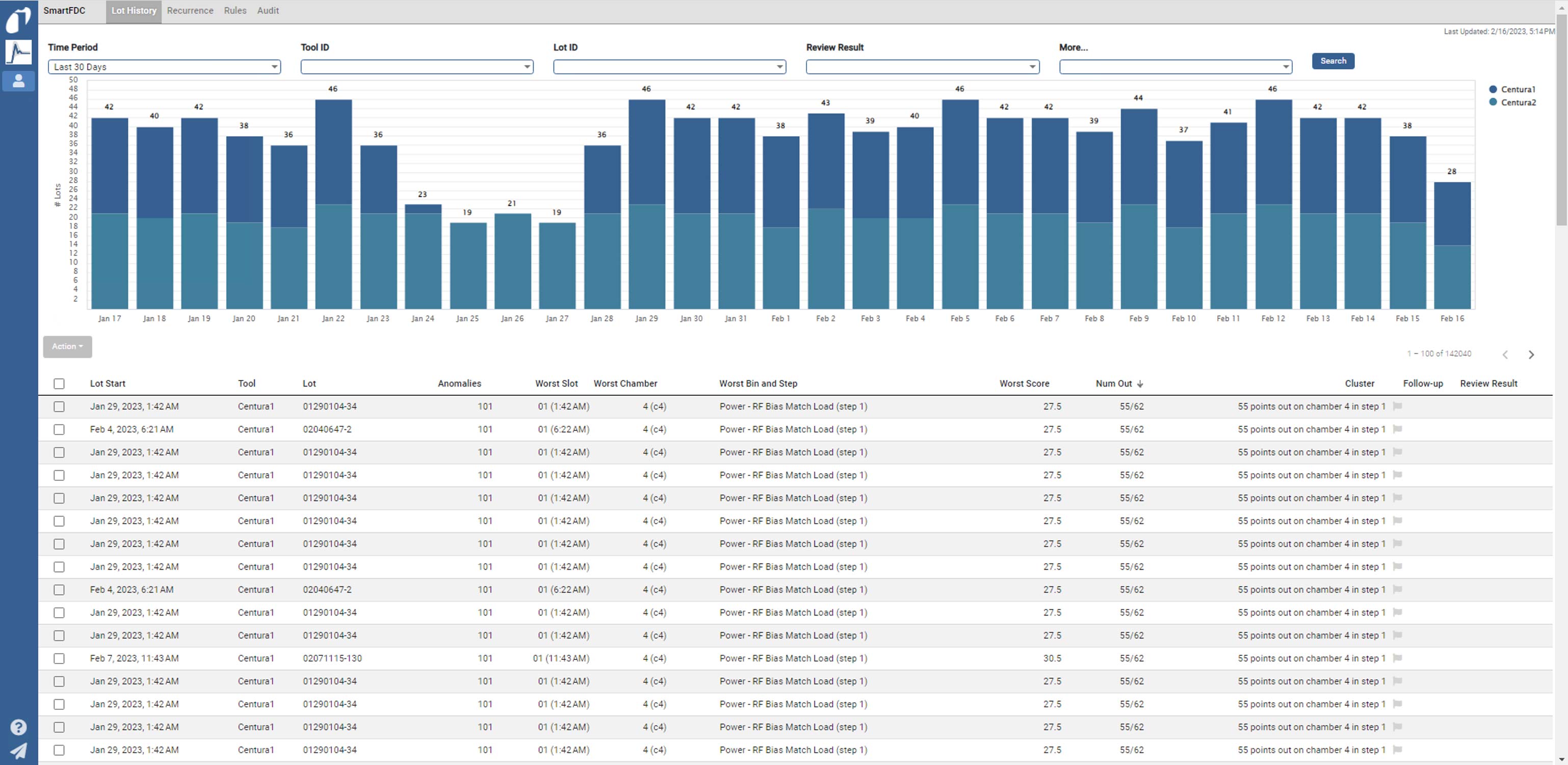

Using Machine Learning technologies, SmartFDC empowers engineers with easy-to-use tools focused on reducing product risk and rapidly resolving production issues.

SmartFDC reduces the time to implement a Fault Detection program, maximizes excursion detection capabilities, and provides powerful analytical tools to engineers of all skill levels.

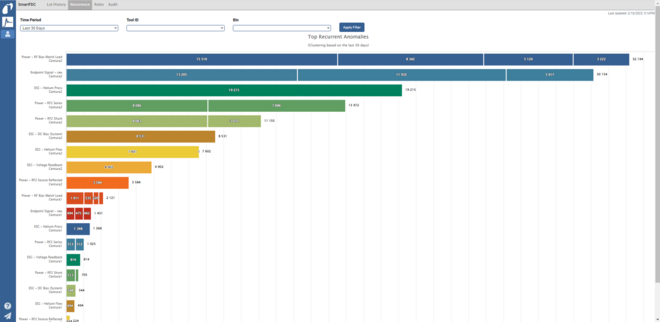

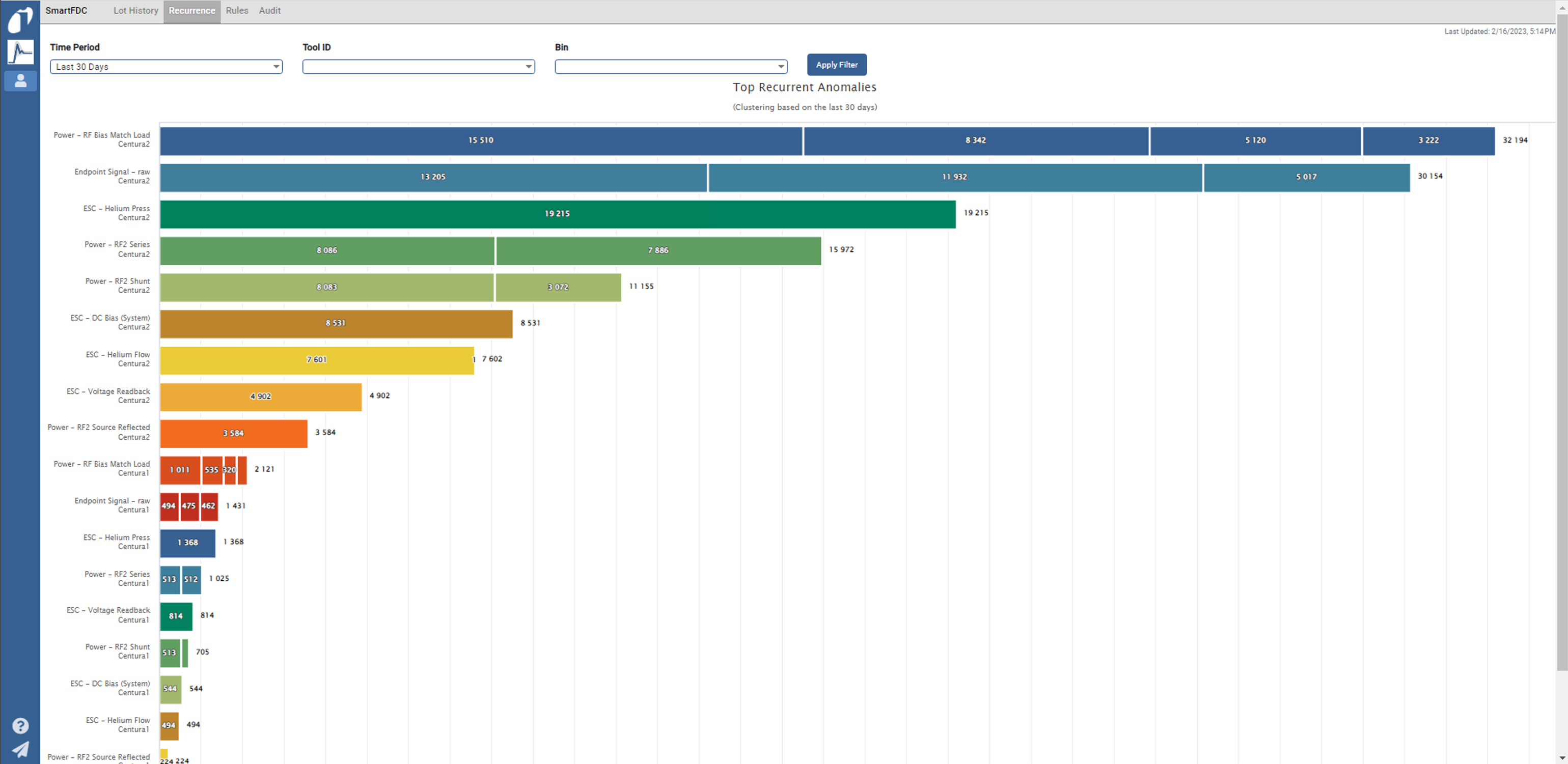

Unparalleled Machine Learning Fault Detection

INFICON’s SmartFDC System automatically translates collected data into meaningful information using machine learning technology. This information is used to provide unique insights into tool and process capability. Working alongside domain specific FDC techniques, our powerful unsupervised Machine Learning methods detect when changes occur in the process and give engineers the tools to identify and correct issues quickly.

Advantages

- Automatic Machine Learning

- Integration 3rd Party FDC Data

- Edge or Cloud Computing

- Engineering Analytical Tools

Analytical Tools for All Engineers

The SmartFDC Machine Learning algorithms reduce product risk and rapidly resolve production issues while automatically providing Fault Detection and Classification (FDC) coverage to.

Engineers of all skill levels have access to the automated and easy to interpret ML analysis results. This reduces the time to detect inline issues and diagnose excursions identified by the system.

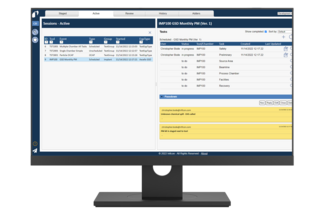

Augment Existing FDC Systems

Merge Machine Learning and engineering experience into a single intuitive platform. SmartFDC architecture enables factories to add capabilities to existing 3rd party FDC systems, including the INFICON FabGuard® FDC System, with ML technology that can target specific process areas or broadly cover the entire facility.