Vacuum Feedthroughs & More

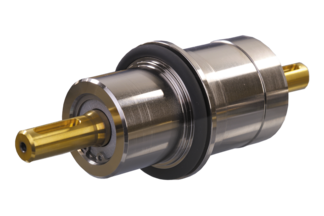

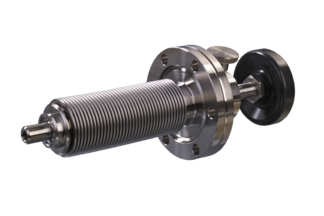

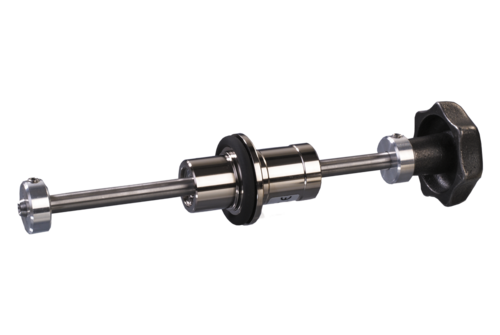

Rotary/Linear Motion Feedthrough

Drop-in Options

Revolutionize your vacuum gauge experience with us!

INFICON's huge variety of mechanical feedthroughs offers the right device for all demanding applications, no matter if it serves e.g. in coating application chambers or in your applied research project under laboratory conditions.

The available flange designs ISO-KF/ISO-K and CF corresponds to our fitting line. All feedthroughs are suited to work in vacuum systems with leak rates up to 1 x 10-9 mbar•l/s. For UHV an all metal designed feedthrough is also available.

Advantages

- Two FPM shaft seals

- Direct push/pull and rotary actuation

- With locking ring and optional anti-rotation device

- 2011/65/EU RoHS compliant

Specifications

FCH016-H

FCH025-H

FCH040-H

| Vacuum connection | DN16 ISO-KF | |

| Feedthrough/seal | FPM | |

| Shaft connection | M3/Ø5mm | |

| Travel | mm | 50 |

| Shaft load | ||

| Radial force at max. travel | N | 10 |

| Torsion torque | Nm | 2 |

| Tightness, static | mbar•l/s | 1 x 10-9 |

| Pressure (absolute) | 1 x 10-8 mbar...1bar | |

| Operating temperature | °C | 50 |

| Bakeout temperature | °C | 110 |

| Materials exposed to process media | stainless steel 304/1.4301, aluminum 6082 | |

Weight

| kg | 0.1 |

| Vacuum connection | DN25 ISO-KF | |

| Feedthrough/seal | FPM | |

| Shaft connection | M4/Ø8mm | |

| Travel | mm | 100 |

| Shaft load | ||

| Radial force at max. travel | N | 15 |

| Torsion torque | Nm | 8 |

| Tightness, static | mbar•l/s | 1 x 10-9 |

| Pressure (absolute) | 1 x 10-8 mbar...1bar | |

| Operating temperature | °C | 50 |

| Bakeout temperature | °C | 110 |

| Materials exposed to process media | stainless steel 304/1.4301, aluminum 6082 | |

Weight

| kg | 0.2 |

| Vacuum connection | DN40 ISO-KF | |

| Feedthrough/seal | FPM | |

| Shaft connection | M6/Ø12mm | |

| Travel | mm | 150 |

| Shaft load | ||

| Radial force at max. travel | N | 30 |

| Torsion torque | Nm | 20 |

| Tightness, static | mbar•l/s | 1 x 10-9 |

| Pressure (absolute) | 1 x 10-8 mbar...1bar | |

| Operating temperature | °C | 50 |

| Bakeout temperature | °C | 110 |

| Materials exposed to process media | stainless steel 304/1.4301, aluminum 6082 | |

Weight

| kg | 0.3 |

Part Number

| Part Number | Description |

| FCH016-H | |

| 214-320 | Rotary/linear feedthrough, DN16 ISO-KF |

| 214-072 | Anti-rotation device, DN16 ISO-KF |

| FCH025-H | |

| 214-322 | Rotary/linear feedthrough, DN25 ISO-KF |

| 214-073 | Anti-rotation device, DN25 ISO-KF |

| FCH040-H | |

| 214-324 | Rotary/linear feedthrough, DN40 ISO-KF |

| 214-074 | Anti-rotation device, DN40 ISO-KF |

Downloads

Datasheets

Dreh-/Schiebedurchführungen ISO-KF DE

pdf

•

275,0 KB

•

German

•

Datasheets

Terminales de paso de movimiento lineal/giratorio ISO-KF ES

pdf

•

274,2 KB

•

Spanish

•

Datasheets

回転式/直線状モーションフィードスルー ISO-KF JA

pdf

•

367,1 KB

•

Japanese

•

Datasheets

로터리/선형 동작 피드스루 ISO-KF KO

pdf

•

315,5 KB

•

Korean

•

Datasheets

旋转/直线运动馈入装置 ISO-KF ZH

pdf

•

362,6 KB

•

Chinese

•

Datasheets

Rotary/Linear Motion Feedthroughs ISO-KF EN

pdf

•

274,3 KB

•

English

•

Datasheets

3D Files

FCH016-H anti-rotation device

zip

•

36,4 KB

•

3D Files

FCH016-H feedthrough

zip

•

50,0 KB

•

3D Files

FCH025-H anti-rotation device

zip

•

33,4 KB

•

3D Files

FCH025-H feedthrough

zip

•

51,5 KB

•

3D Files

FCH040-H anti-rotation device

zip

•

36,7 KB

•

3D Files

FCH040-H feedthrough

zip

•

54,6 KB

•

3D Files