3D Scanner

3D Scanner System

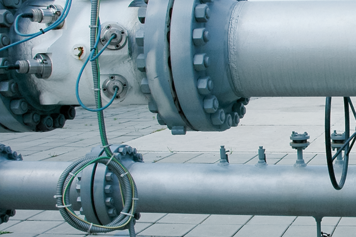

I-Guide3D 350 Scanner: Maximum Precision for Fully Automated Leak Test Systems from our partner Visionerf.

Now available at Visionerf.

Millimetric precision is crucial in fully automated leak test systems. On a refrigerator or heat pump production line for example, the position of all test points must be determined with millimetric accuracy. Manufacturing tolerances of +/- 1 cm in all directions for the position of solder joints have long been a challenge of robotic leak testing.

For more information contact Visionerf.

Four Components for Your Intelligent Test Station

The 3D Robotic Leak Testing System solution includes four components that complement each other perfectly:

- Ecotec® E3000 – multi-gas leak tester

- I-Guide3D 350 – intelligent 3D Sensor

- I-Tip – innovative and patented sniffer tip

- Calibration leak – test leak for fully automated calibration

Advantages at a glance

- Software is optimized for finding joints by looking for change in diameter

- Robot path planning is done by the software for optimized cycle time

- Software does collision check all along the robot path

- Software checks for singularity of the robot

- No robot programming needed to convert x-y-z-coordinates into robot movement

Specifications

| Resolution | <= 0,01mm |

| Scanning volume | 350 x 350 x 250 mm (13,8x13,8x9,8“) |

| Minimum distance to test object | 450 mm (17,7“) |

| Dimensions | 270 x 53 x 130 mm |

| Weight | 2,7 kg |

| Safety class | 3R |

The system is used in the following markets