Factory Dashboard

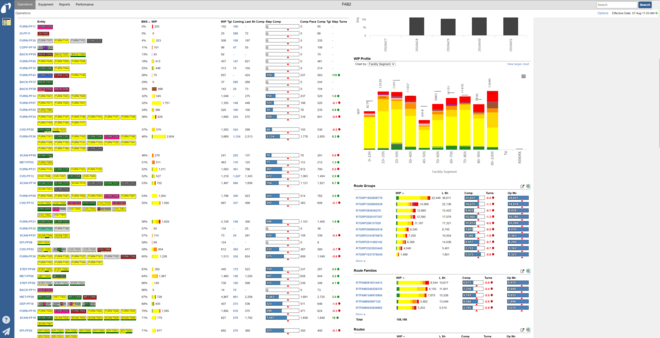

Actionable Information from a Real-Time Factory View

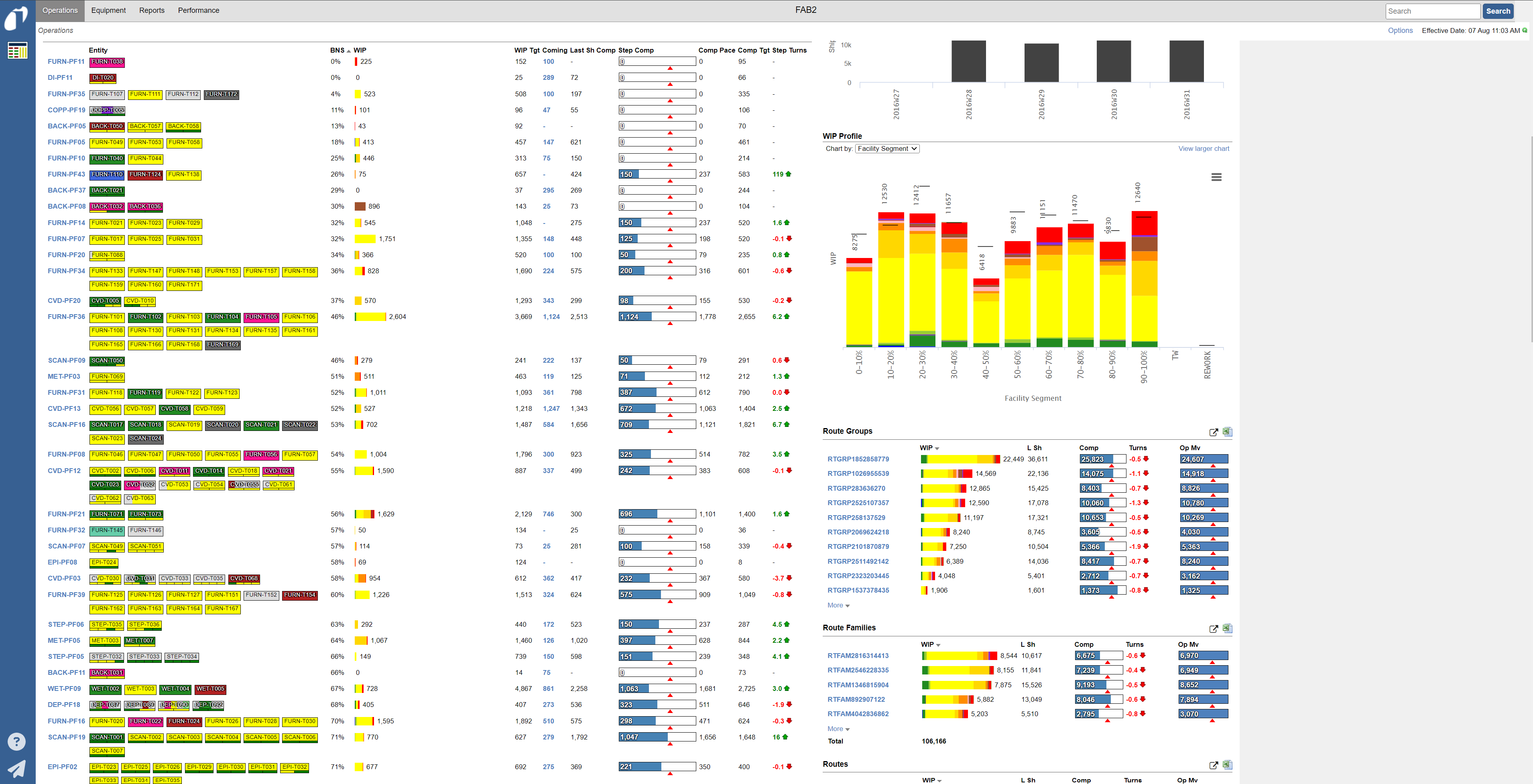

The Factory Dashboard is the principal operations reporting tool used by industry-leading fabs around the world.

Everything You Need to Know About Now

The Factory Dashboard is designed to provide a web-based user-friendly and concise overview of the factory's real time status and priorities. At a quick glance, it provides a comprehensive visibility into operations, maintenance, and engineering activities to drive focus and efforts to meet real-time manufacturing needs.

Real Time Bottleneck Identification and Ranking

The Factory Dashboard incorporates production targets to identify and rank bottleneck tools and processes. Production managers can easily identify which equipment might have trouble meeting goals for the shift, and direct timely action based on real data.

- Starts and Outs

- Priority Lots

- Rework

- Machine Status

- Machine Issues and Scraps

- Upcoming Maintnenance

- Equipment Availability

- Bottleneck

- Activities

- Goal Tracking

Advantages

- Enables quick response to machine and WIP issues

- Increases all factory personnel awareness

- Improves reaction time of personnel

- Improves alignment of operations with planning

- Reduces data gathering time

- Creates a common storage location for Operational information

- Improves tool logging

- Impresses auditors and customers

- Improves ability to adapt to changes in demand

- Enables the capability for other productivity improvement projects

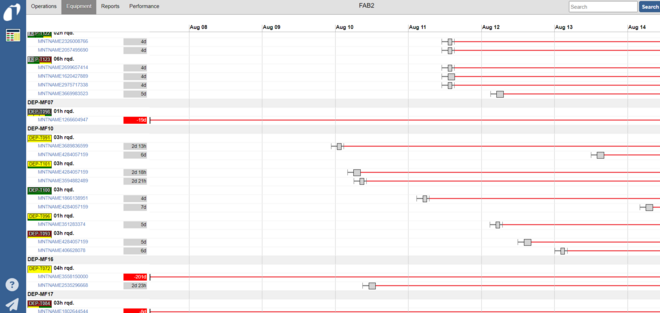

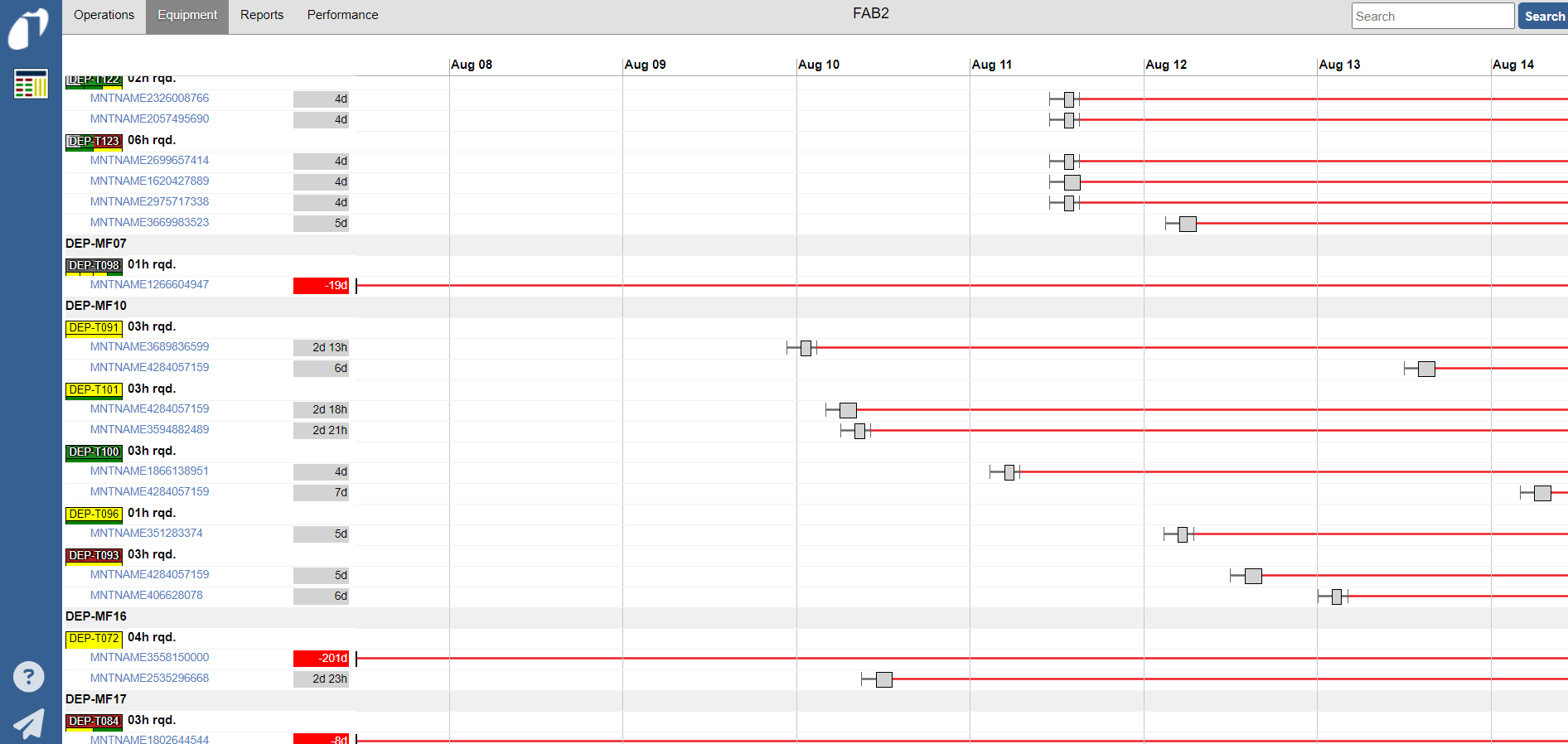

Equipment Insight

In addition to the Operations-related information, the Dashboard includes equipment and maintenance information. Managers can quickly see down tools, useful summary statistics, as well as upcoming preventative maintenance activities.

The Maintenance view shows a calendar view of upcoming preventative maintenance activities. The system enables interaction allowing the scheduling or rescheduling of maintenance events from the user interface.