Transforming Gas Leak Detection with Infrared and Digital Technology

Next-generation leak detection tools and digital gas leak detection are helping utilities meet regulations, enhance safety, and optimize leak survey.

The Shift to Digital Gas Leak Detection for Utilities

From satellites to handheld infrared (IR) tools, next-generation leak detection tools are making detection faster, more precise, and far easier to manage.

While no single technology fits every situation, combining the right tools—satellites, drones, laser scanners, and portable IR leak detection devices—enables a comprehensive and precise approach. The new technologies are non-invasive, easy to work with, and often deliver digital results that can be easily stored and uploaded.

Together, these tools bring leak detection into the digital era, improving safety, compliance, and cost efficiency while providing vast efficiency improvements to gas network survey processes. However, the industry is moving slowly, and legacy gas detection methods still dominate in many areas.

The shift toward digital detection is not only driven by advances in technology, but also by growing regulatory pressure. Governments around the world are mandating tighter control of methane emissions:

- The EU Methane Regulation (2024/1787) requires producers to cut emissions not only within the EU but across the entire global supply chain.

- Several U.S. states have adopted similar rules, turning leak detection from best practice into legal necessity.

These mandates are accelerating adoption of digital, high-performance solutions—like infrared detectors, satellites, and cloud-integrated software—designed to meet stricter compliance demands while improving operational efficiency.

Why Modern IR Leak Detection Tools Outperform Traditional Methods

Traditional leak detection methods rely on chemical reactions. For example, flame ionization detectors (FID) burn gas and measure the resulting ionized particles. While accurate, these tools tend to be heavy and cumbersome. Semiconductor sensors are lighter and faster but often less reliable and repeatable over time; they can also take a long time to reset after exposure to high gas concentrations.

Modern IR absorption technology sidesteps chemical reactions entirely by measuring the specific wavelengths of light absorbed by gas molecules, enabling non-contact detection and faster results.

Most laser-based instruments on the market are intended for remote scanning to detect the presence of gas, while handheld IR detectors are used for pinpointing exact leak locations and quantifying emissions. Satellites and drones can extend coverage to entire regions or isolated areas, supporting scalable detection strategies.

Precision at Ground Level

To confirm and locate leaks, it is necessary to get down to ground level with a hand-held IR instrument. Infrared instruments for work at close range analyze samples from the atmosphere in a chamber inside the instrument.

An assortment of attachments, similar to those used with traditional close-range detectors, has been developed to help pinpoint the location of leaks using an IR instrument, such as probes for getting into cavities and corners. For inspecting underground gas lines, a small trolley with an air-trapping mat can be pushed along the pipeline route above ground.

Once gas has been detected, it needs to be analyzed to determine whether it is from a pipeline leak or just naturally occurring methane, also known as swamp gas. Both swamp gas and natural gas contain methane. But natural gas also has a component that does not occur in swamp gas, and this is ethane. So, the presence of ethane is the marker for natural gas.

Digital, Real-Time Reporting

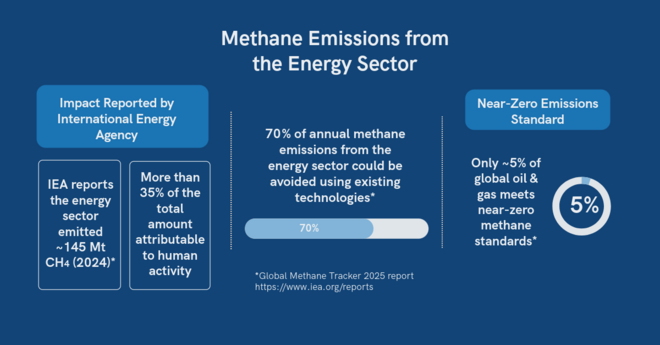

Methane emissions remain at stubbornly high levels, with the fossil fuel sector alone responsible for nearly one-third of all human-caused methane emissions, according to the International Energy Agency (IEA). The IEA also reports that around 70 percent of these emissions from the energy sector could be avoided using existing technologies.

In this context, connectivity and digital reporting features have become essential tools in modern leak detection. Today’s IR instruments are designed to meet these challenges. Many now include:

- Bluetooth for seamless data transfer

- GPS for accurate location tagging

- Cloud software integration for streamlined compliance reporting

These features allow operators to:

- Log and geotag every scan, enabling faster and more precise leak detection

- Upload data in real time, supporting compliance with increasingly strict regulations

- Bridge the gap between satellite monitoring and on-the-ground inspection, improving transparency and reporting

“One particular advantage of the IR instrument that we use is that it has a Bluetooth® connection that we can use with our own software. The data is logged and uploaded within seconds, making the record keeping so much easier,” says Bas Hermans, Operations Director at Intero – The Sniffers.

With advanced instruments like IRwin Methane Leak Detector, INFICON is helping utility operators around the world modernize their leak detection strategies—ensuring safety, compliance, and cost-effectiveness in a rapidly evolving regulatory landscape.

Preparing for a Hydrogen Future

As the energy industry explores hydrogen as a cleaner alternative to natural gas, IR tools remain relevant—especially in blended fuel scenarios. While pure hydrogen detection is still developing, the current generation of tools will continue playing a key role in mixed gas environments for years to come.

Preparing for a hydrogen future? Read our article on ensuring safety in hydrogen-blended gas environments.

Interested in reading the full article?

Read the complete version on Petro Industry News!