Reducing Scrap in Brazing Furnaces with INFICON Augent® OPG550

Leak Detection in Brazing Furnaces: A new approach to avoid scrap and save money.

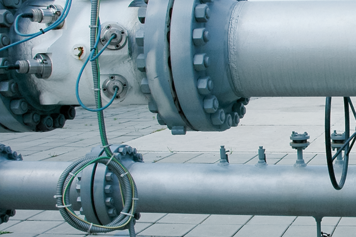

In the automotive industry, precision and reliability are crucial, especially in the production of radiators used in vehicle cooling systems. One of the key challenges in brazing processes is the presence of undetected air leaks. lf these leaks are not identified in time, they will damage the integrity of the brazing joints, leading to defect components that fail to meet customer quality demands.

Air leaks in brazing furnaces can cause oxygen ingress, disrupting the controlled atmosphere required for brazing, and ultimately result in weak or incomplete braze joints. The consequences of undetected leaks include increased scrap rates, costly rework, and potential failures in the field. As a result, suppliers face warranty claims and reputation damage.

Ensuring effective monitoring of vacuum atmospheres is therefore essential for maintaining production efficiency, reducing material waste, and delivering high-quality components. Particularly the ability of early leak detection is essential. Using a self-plasma optical emission spectrometer (SP-OES), like Augent OPG550, addresses this issue in a cost-efficient way. Augent OPG550 provides in situ brazing atmosphere monitoring including leak detection, is easy to integrate, and can survive under harsh conditions. A detailed explanation of the technology is given in a later section.

Challenge: Find a New, Robust, Cost-efficient Leak Detection Solution

Leak detection was mainly done during during regular maintenance or in case of failures. It is very challenging, because of tool down time and high time demand. Additionally there is a helium contamination in the vacuum chamber.

In brazing furnaces there is an additional challenge of contamination due to the usage of oil diffusion pump units for vacuum generation. The disadvantage of this technology are oil residuals which can be found in the process environment. That is a problem for traditional methods utilizing mass spectrometers. The pressure rate--of-rise leak detection methods also does not fulfil the requirements, because it is not real-time capable and very time-consuming for large vacuum chambers.

The customer was looking for a robust, cost-efficient atmosphere monitoring and leak detection system that could survive at least one preventive maintenance cycle. Using an in-situ SP-OES solution like Augent OPG550 is a new approach to overcome the challenges mentioned above.

Solution: Integration of Augent OPG550 in the Brazing Furnace

To address the requirement of in-process leak detection, the company integrated Augent OPG550 into their brazing furnace. This sensor is used for atmospheric monitoring and leak detection, total pressure measurement, and other gas analysis applications.

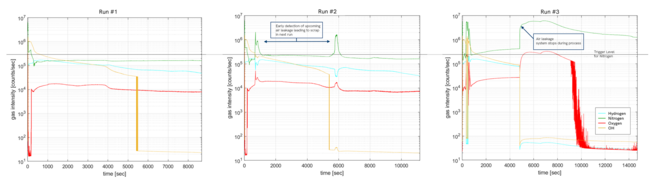

The SP-OES technology provides precise and reliable atmosphere monitoring, contamination and leak detection. Leaks could be detected when they happen or even when they are about to appear. The signalization was implemented by an output signal in traffic-light style. Therefore, it is possible to detect leaks before getting severe and generating scrap. The OPG550 is able to survive under this harsh environment for the required time. On top of that, it is easy to clean the sensor cell during maintenance and further extend the lifetime. The sensor has now been running for one year, with just cleaning during regular maintenance at the end of its lifetime, the sensor cell can easily be replaced, while the electronics will be re used, therefore the total cost of ownership (TCO) stays low. Besides the optical plasma analysis for leak detection, the OPG550 in this application also acts as a redundant pressure sensor to increase the system's reliability.

The graphs above show gas intensity for a good run, early detection, and an air leak during process. The results show that this solution can act as predictive maintenance and a fault detection system. The additional data provided by the OPG gives a more sensitive signal compared to a pure vacuum sensor.

Results: Enhanced Quality Control and Reduced Waste

With the new system in place, the company experienced a significant reduction in scrap. Even in the challenging environment of brazing furnaces, where magnesium and residue accumulation are common, Augent OPG550 delivered a consistent performance. Despite needing periodic sensor maintenance, such as cleaning the optical feedthrough, the benefits far outweigh this minor upkeep requirement. By leveraging the SP-OES leak detection technology, the company achieved:

- Significant Reduction in Scrap:

Air leaks were detected in real time, preventing defective components from moving further down the line or starting a new production run. - Improved Process Efficiency:

Faster identification of issues led to reduced rework, maintenance, and increased overall productivity, as it provided a preventive maintenance solution. - High ROI:

Since a production run could cost several thousands of Euros, the ROI is given by detecting just a few leaks. - Cost Savings:

Minimizing material waste translated to substantial financial benefit.

Adaptability for other Markets

SP-OES technology provides significant advantages beyond this specific application. lt can be adapted for industries that use vacuum furnaces, ensuring precise and efficient atmosphere monitoring, contamination control and leak detection. Sectors such as aerospace, aviation, electronics manufacturing, medical technology, and industrial production benefit from reduced waste, improved quality control, and optimized manufacturing processes. By integration of an Augent" OPG550 companies can enhance operational efficiency, minimize production losses and achieve greater reliability in their processes.

Offering RS232, PROFINET, and EtherCAT, this sensor could be integrated very easily to any process control system. The intelligent output signals avoid the installation of additional software and challenging data analysis. For fast start up and convenient data visualization there is a software GUI available.

Conclusion

By integration of Augent OPG550, this automotive component manufacturer successfully overcame a major production challenge, optimizing both quality control and cost efficiency. This case underscores the value of advanced atmosphere monitoring and leak detection in manufacturing environments, proving that even in demanding conditions, innovative solutions can drive measurable improvements. It is overall a robust, cost-efficient solution for vacuum furnaces.

In addition to leak detection, Augent OPG550 could also offer residual gas detection. As it is a dual gauge, it could act as an additional advanced total pressure sensor or even replace existing vacuum gauges and add more features to the process monitoring. Due to its easy tool integration, this sensor technology is the perfect solution for in situ leak detection and advanced process control in environments where RGAs cannot be used.

Augent OPG550: Dual Gauge for Optical Gas Analysis and Total Pressure Measurement

The INFICON Augent OPG550 optical plasma gauge is a compact and intelligent solution for vacuum gas monitoring.

Augent OPG550 combines two sensor technologies into one compact device for gas type monitoring from 1 x 10-7 to 5 mbar and measuring total pressure from 1 x 10-7 mbar to atmosphere at the same time. Augent OPG550 is protected by an integrated Pirani sensor to switch off plasma above 20 mbar. The fast optical measurement al\ows the detection of any type of gas in principle.

Operational Principle, Application, and Integration

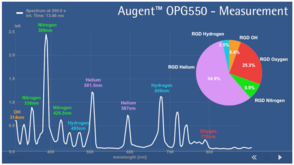

Augent OPG550 functions as an optical plasma gauge, utilizing an inverted magnetron plasma cell to generate plasma. A high voltage within the plasma cell accelerates electrons from chamber walls.

towards the central anode, propelled into circular motion by the existing magnetic field. These electrons col\ide with residual gas atoms, resulting in the generation of a mixture of charged particles and the formation of plasma. The ionization current is directly proportional to total pressure

The resulting plasma emits light, the spectral characterlstics of which depend on the gas mixture This emitted light passes through an optical window for external observation. A light analyzer digitizes the light signal based on wavelength and intensity. The intelligent algorithm of Augent OPG550 fits the optical data to known gas spectra, facilitating identification of gas species and mixture composition This facilitates the delivery of pre-analyzed data, the activation of alarms, and the utilization of values for monitoring or controlling customer tools.

The big advantage of this concept is that it delivers leak detection as a basis in addition to other things like pressure measurement, gas analysis, moisture detection, endpoint detection and more, depending on specific application or requirements. lt's very easy to integrate the sensor into any tool control system, as it offers RS232 and an analog output as weil as standard field buses like EtherCAT or PROFINET. Therefore, it is the ideal device for tool manufacturers and end users who are looking for an intelligent sensor solution.

As this sensor offers different interfaces and intelligence, it can be used as a tool integrated measurement solution, which does not require additional software and/or trained personnel.

On-Demand Webinars about Augent OPG550

lf you're interested in learning more about the technology behind our solutions and how they can support your process, we recommend watching one of our on--demand webinars. You can access them anytime online:

Downloads

Related Markets

From electrode production to end-of-line testing

Vacuum is used more often to guarantee clean environment and is needed for several processes, then without vacuum they do not work.

Reliable leak testing in an evolving industry. Changes in the automotive industry make leak testing even more important.