LDAR Programs and Leak Detection: A Fast Track to Climate Progress

State-of-the-Art Leak Detection and Repair Tool to Cut Methane

Reducing methane emissions is one of the fastest and most effective strategies to cut the climate footprint of fossil fuels. Today, LDAR (Leak Detection and Repair) programs are emerging as essential tools to cut methane emissions across the energy sector. As industries seek better industrial emissions management, implementing a robust LDAR program can deliver measurable environmental and compliance benefits.

Tackling Methane Emissions with Leak Detection and Repair Technologies

It's important to ensure that renewable alternatives, such as biomethane, do not become significant environmental threats. Methane—the primary component of both natural gas and biogas—is a highly potent greenhouse gas. Over a 20-year period, it has more than 80 times the global warming potential of carbon dioxide. Since the Industrial Revolution, methane emissions have contributed to roughly 30% of observed global warming, making it a top priority for climate action. Whether from fossil or renewable sources, uncontrolled methane emissions pose a major challenge for industrial emissions management.

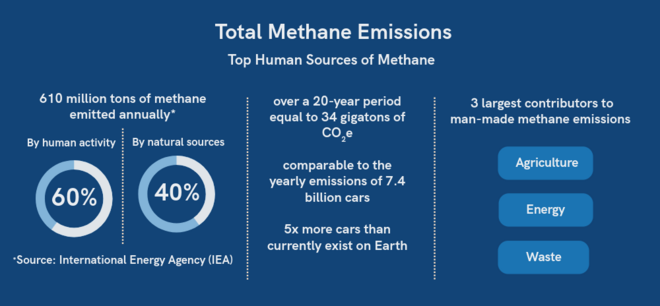

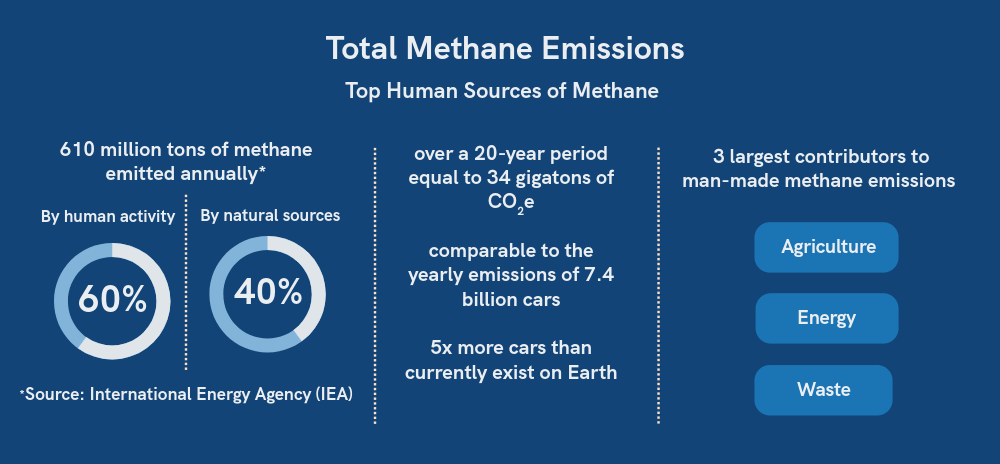

According to the International Energy Agency (IEA), human activity accounts for around 60% of the estimated 610 million tons of methane released annually. Agriculture, energy, and waste are the top sources—showing how widespread the issue is. Over a 20-year period, these emissions would amount to 34 gigatons of CO₂e—comparable to the yearly emissions of 7.4 billion cars, which is five times the number of vehicles on Earth today.

As nations strive to limit temperature rise to 1.5°C, the urgency to cut methane emissions continues to grow. Leak detection and repair technologies play a critical role. Advanced LDAR tools are designed to locate and cut methane leaks quickly and efficiently, helping industries meet environmental standards while supporting sustainability. Although eliminating all emissions isn't feasible due to technical and economic constraints, large reductions are both possible and necessary. Each sector has its own set of challenges, but the energy sector—particularly oil and gas—has already made progress by setting reduction targets and adopting advanced industrial emissions management practices.

A critical part of this transformation is improving how emissions are detected and quantified. Historically, leak detection focused mainly on safety. However, as sustainability becomes a key priority, industries are adopting innovative leak detection and repair technologies to boost environmental performance and meet global climate goals.

Large-scale solutions such as satellites, drones, and fixed sensor networks offer valuable oversight. However, effective methane mitigation ultimately depends on close-up, ground-level inspection. Many leaks stem from small yet critical components, such as valves, seals, and flanges, that cannot be monitored remotely with the necessary precision. This is where handheld detection tools are indispensable.

IRwin: Advancing Leak Detection for a Sustainable Future

Among the most effective tools in modern LDAR (Leak Detection and Repair) programs is IRwin®—a rugged, intuitive, and intrinsically safe handheld methane detector developed specifically for demanding field applications.

IRwin uses proprietary infrared (IR) technology to detect methane from the low ppm range all the way up to 100% CH₄ by volume. What sets it apart is its resistance to common interference sources such as moist air, ground contamination, vehicle exhaust—and the risk of flame-outs, which are a known issue with certain other sensor technologies like flame ionization detectors (FIDs). These disturbances often lead to false alarms, interrupted measurements, and delayed investigations, significantly reducing the efficiency of leak detection work. By avoiding these issues, IRwin ensures faster, more reliable inspections and a smoother workflow in the field.Its fast response and recovery times, low cross-sensitivity, and stable performance in varying field conditions make IRwin ideal for pinpointing leaks efficiently. Even after detecting high methane concentrations, the instrument recovers quickly—ensuring minimal downtime during inspections.

Perhaps IRwin’s greatest strength lies in its ability to achieve precision at the most granular level. It allows technicians to thoroughly inspect every part of a facility, pinpoint the precise location of a leak, and verify repairs on-site. Without this level of detail, leaks can remain undetected, which undermines broader detection systems and emissions targets.

With its effective accessories and seamless digital documentation capabilities, IRwin helps ensure compliance, improve operational efficiency, and enhance data quality, making it a valuable addition to any company's emissions reduction toolkit.

In the broader effort to reduce methane emissions, handheld technologies like IRwin are not just supportive—they are essential. They provide the last-mile accuracy needed to bridge the gap between detection and action, playing a vital role in securing a cleaner, safer, and more climate-resilient future.

Identifying, Measuring and Reporting of Methane Emissions at the Heart of the EU Methane Regulation

In the fight against climate change, the European Union has taken a significant step forward with the introduction of Regulation (EU) 2024/1787.

Read more about the importance of identifying, measuring and reporting of methane emissions!