Implementing FabGuard® EPI for Monitoring

FabGuard® FDC from INFICON offers a smart monitoring and notification system designed to ensure clean recipes are executed on time.

FabGuard® FDC from INFICON offers a smart monitoring and notification system designed to ensure clean recipes are executed on time. By utilizing Equipment Performance Indicators (EPI) and automated reporting, engineers can maintain precise process control with minimal manual intervention.

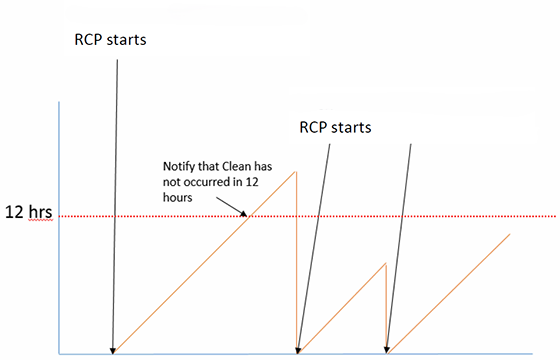

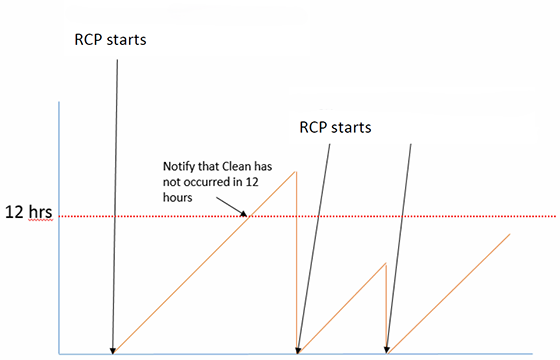

FabGuard tracks clean recipe execution through an event detection system. When a clean recipe starts, the tool event CEID (Collection Event Identification) triggers, while a visual Time Since Event Bin helps identify any irregularities by tracking execution intervals.

Using an EPI timer, engineers can monitor the time since the last clean recipe execution. The system includes a logic filter to ensure the timer only tracks the relevant recipe, while also verifying the execution status before stopping the timer. This approach guarantees accurate logging of the process.

To address the need for recipe-specific tracking, FabGuard captures the recipe ID and introduces a brief 3-second delay to differentiate between start and stop events, reducing false positives. Filtering by recipe name ensures that only relevant clean recipes are reported.

Custom reports are generated to track recipe execution times and trigger automated alerts when a recipe hasn’t run within 12 hours. Simulated alarms provide engineers with real-time insights, allowing them to intervene and prevent issues before wafer processing begins.

The Impact: Improved Process Control & Reliability

By configuring just three EPI triggers and a single report, FabGuard helps fabs to:

- Prevent wafer processing under unintended conditions, reducing scrap and yield loss.

- Minimize process variability and tool failure, leading to better chamber performance.

- Automate monitoring, reducing the need for manual oversight and ensuring consistent chamber operation.

This approach enhances process reliability and helps maintain semiconductor fabrication stability by minimizing unexpected deviations.

Optimizing Semiconductor Manufacturing with FabGuard

In the fast-paced world of semiconductor manufacturing, early detection of chamber inconsistencies is crucial for maintaining high yields and stable processes. With FabGuard’s EPI system, fabs can easily monitor clean recipe execution, receive automated alerts, and act quickly before problems escalate.

Ready to optimize your semiconductor manufacturing process?

FabGuard has the tools you need for precise monitoring and control. Contact us today to learn how we can enhance your operations!