Electric Motor Testing for EVs: Preventing Failures with Modern Leak Detection Solutions

Leak Tests with Tracer Gas at the Rework Station Support Quality Control in Electric Drive Motors.

As EV adoption grows, electric motor testing and leak detection are becoming vital for ensuring quality and performance. The pressure on manufacturers to deliver flawless components at scale has never been higher. Among the most critical parts are the electric drive motors and their integrated cooling jackets—where even a minor coolant leak can compromise performance, trigger warranty claims, or delay vehicle delivery.

To strengthen quality control, many EV manufacturers now use tracer gas-based leak testing methods. These techniques are redefining reliability and efficiency on the assembly line—particularly at rework stations, where failed units are inspected and repaired.

From Guesswork to Precise Leak Test of Electric Drive Motors

When the cooling jacket of an electric drive motor fails its final inspection due to a suspected leak, rapid and accurate fault identification at the rework station is essential. Traditionally, methods like soap spray, visual checks, or pressure decay testing leave too much room for missed micro-leaks and inconsistent results, especially when the internal volume is large and small temperature swings dampen pressure changes.

By using tracer gas for leak detection, technicians can now detect leaks that previously went unnoticed, such as faulty welds or seals, and fix them faster. The process involves injecting a safe, low-concentration tracer gas into the motor housing. Tracer gas detectors then scan for escaping gas, allowing precise identification of leak locations—even in complex joint configurations or hard-to-access areas.

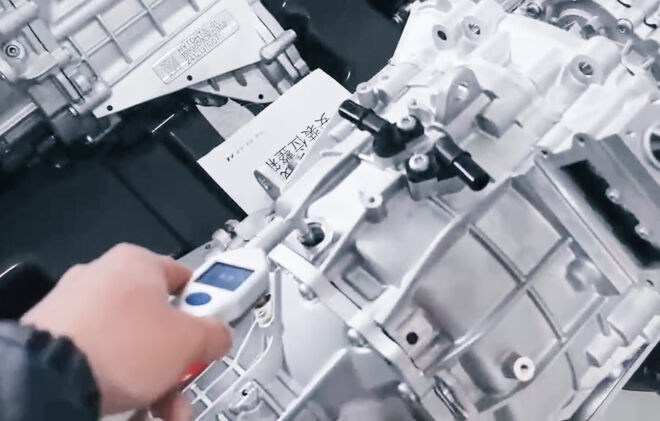

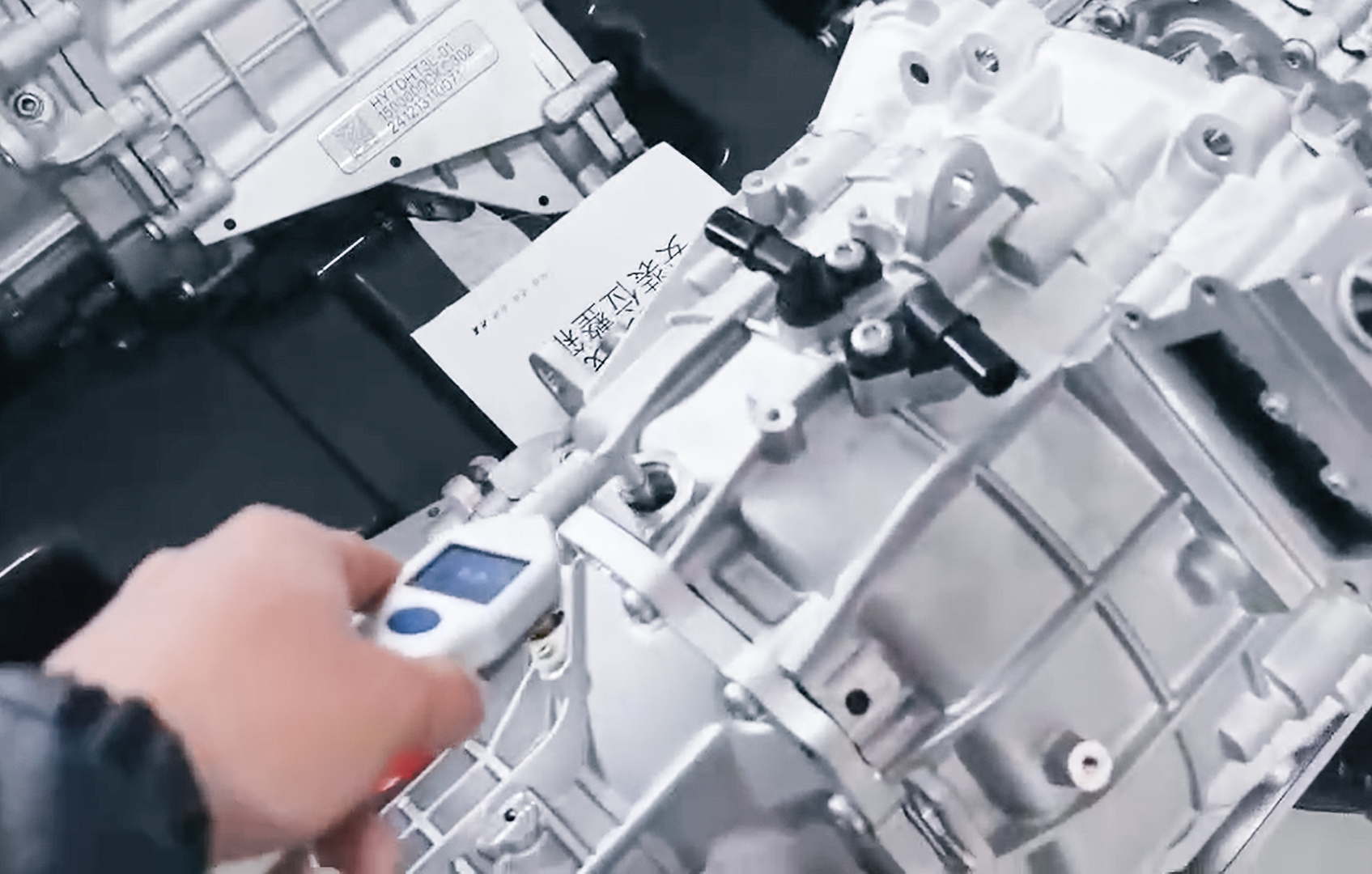

At the rework station, Lao Wang, senior technical supervisor at a Chinese EV manufacturer, begins the inspection by filling the system with tracer gas—in this case a 5% hydrogen in nitrogen mixture. Then he uses a tracer gas leak detector to scan the motor assembly and shows how easy it is. He carefully moves the handheld probe over the motor’s joints, seals, and pipe interfaces. The detector continuously monitors for trace amounts of hydrogen escaping from the system. As the probe passes over a joint at the bottom of the motor, the device sounds an alarm and the gas concentration reading spikes—clearly identifying the leak location. Lao Wang immediately marks the spot for repair.

Consistent, Trusted Results Across the EV Production Process

What makes the tracer gas method especially valuable is its repeatability and scalability. Unlike older techniques, which depended heavily on operator skill or visual cues, this method delivers clear, repeatable results regardless of unit complexity or operator experience.

That trust is backed by performance data. Since introducing this approach, the electric drive motor production process has seen:

- Leak detection accuracy increase from 70% to 99.7%

- Rework time due to leaks reduced by 80%

- Diagnosis and repair cycle completed in an average of 30 minutes

These gains are not only improving production throughput—leak detection with tracer gas helps ensure that every motor leaving the facility meets the highest quality standards and building trust with the operators who use leak detectors from INFICON daily.

Why It Matters for High-Volume EV Production

As EV adoption accelerates, production efficiency, defect reduction, and aftersales cost control are mission-critical. Leak detection systems like the Sentrac Hydrogen Leak Detector or the Protec Helium Leak Detector from INFICON, in combination with the TGF11 Tracer Gas Filler, directly support:

- Higher yield per shift

- Fewer warranty issues tied to leakage faults

- Faster leak analysis

- Lower warranty cost

Also Interested in the Best Method for Inline Electric Motor Testing?

Discover the most effective ways to test electric motors inline—read more here!