Edge AI: A Semiconductor Process Control Revolution

Smarter, faster decisions right at the edge

Imagine this: You're in the heart of a semiconductor fab, where every second matters and even the slightest delay can spell disaster. Amid the hum of machinery and the activity of wafer movements, there's a looming challenge: traditional process control systems just aren’t fast enough.

In an industry where technology is scaling down to ever-smaller nodes, achieving high yield means mastering both precision and speed. Yet many fabs are held back by traditional process control and centralized AI/ML systems that simply can't keep pace to react in real-time.

When Traditional Systems Fail

In semiconductor manufacturing, a small misstep can result in significant yield loss. Engineers face an uphill battle as they try to detect minute process changes and adjust systems in real time or on a run-by-run (RbR) basis. Traditional AI/ML solutions, deployed on central servers, introduce delays that prove too costly in these time-sensitive environments.

Here’s a common scenario in a busy fab: advanced sensors are picking up critical data, but by the time the information reaches a central server and a decision is made, the window for action has closed. Process faults occur, production lines falter, and the pressure mounts as yields drop. Something needs to change—fast.

Embracing Edge AI

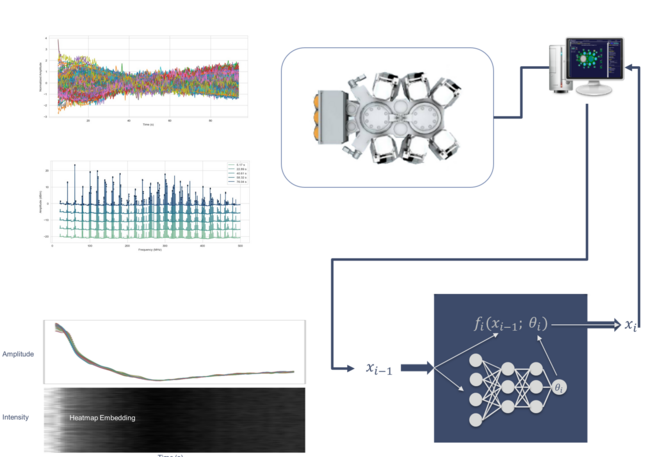

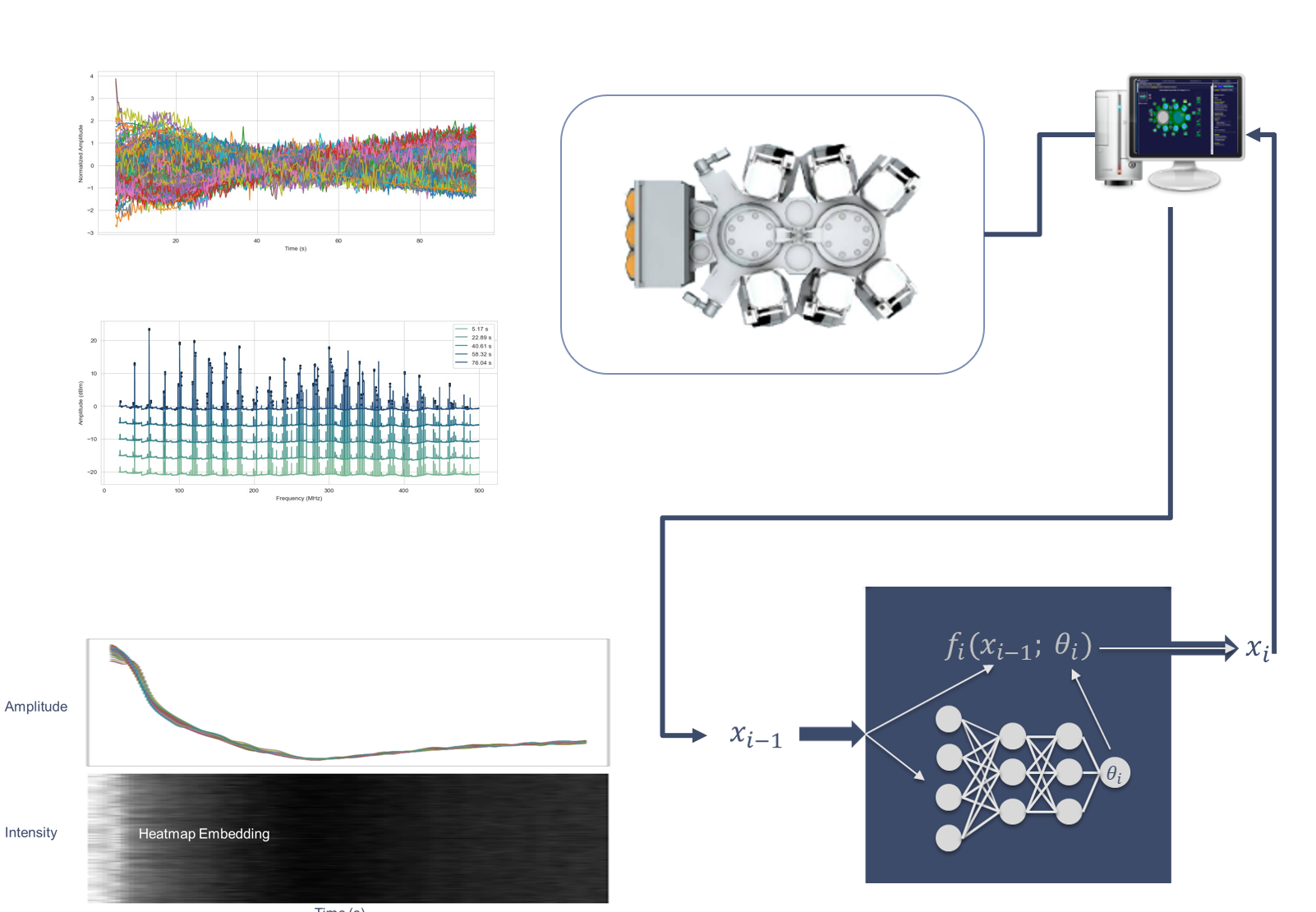

Enter the FabGuard® system from INFICON. In a breakthrough move, FabGuard shifts AI/ML processing to the very edge of the network — right where the action happens. By harnessing the low-latency Libtorch library and the flexibility of PyTorch, FabGuard deploys advanced deep learning models directly at the point of data capture. This innovation means that sensor data is processed in real time, enabling immediate adjustments without the delay of centralized computing.

One striking example of this transformation is in real-time endpoint detection during low open area etch processes. Traditional methods relied on univariate sensor signals, which often failed to capture the complex, multivariate data needed for precise endpoint detection. With FabGuard, deep learning models interpret these multivariate signals on the spot, accurately predicting process endpoints and enabling automatic adjustments. This results in enhanced sensitivity, fewer process faults, and a smoother, more reliable manufacturing process.

Overcoming Anomalies and Ensuring Stability

Fault Detection and Classification (FDC) has long been a challenge in semiconductor fabs. Manual summarization of sensor outputs often left critical anomalies undetected until it was too late. With FabGuard, a deep learning anomaly detection model is deployed at the edge to continuously monitor sensor data, like that from quartz crystal microbalance (QCM) sensors. This model doesn’t wait for human intervention; it identifies and flags anomalies in real time, ensuring that potential issues are intercepted before they impact the production process.

Smarter, Faster, and More Precise Process Control

By embracing edge AI with FabGuard, fabs are witnessing a return on investment in process control:

- Real-Time Processing: Immediate data analysis eliminates latency, leading to faster and more effective decision-making.

- Enhanced Yield: With precise endpoint detection and proactive anomaly identification, production faults are minimized, boosting overall yield.

- Operational Efficiency: Seamless integration with existing systems and automatic model distribution across edge nodes ensures consistent performance across all tools.

- Cost Savings: Reduced waste and improved cycle times translate directly into a significant return on investment.

Your Next Step

The story of FabGuard is one of transformation; turning a critical challenge into a strategic advantage. For semiconductor manufacturers facing the relentless demand for precision and speed, integrating edge AI isn’t just an upgrade, it’s a revolution in process control.

Ready to transform your process control and gain the competitive edge in semiconductor manufacturing? Discover how INFICON’s FabGuard system can help you achieve smarter, faster, and more precise operations. Contact us today or explore our product offerings to take the first step toward a more efficient, future-proof fab.

Embrace the future with edge AI — where every microsecond counts, and every decision drives success.