Why helium bombing does not work for liquid filled parts like battery cells

A common way to test hermetically sealed parts is helium bombing. Parts are stored in a high pressure helium atmosphere for a period of time and tested for escaping helium with a vacuum leak detector. The best known use case for this leak testing method is the leak testing of airbag gas generators.

Some users have tried to leak test hermetically sealed, electrolyte filled battery cells with the helium bombing test method. However, as is explained in this article, this poses severe risks of missing leaks and does not provide a reliable way of leak testing.

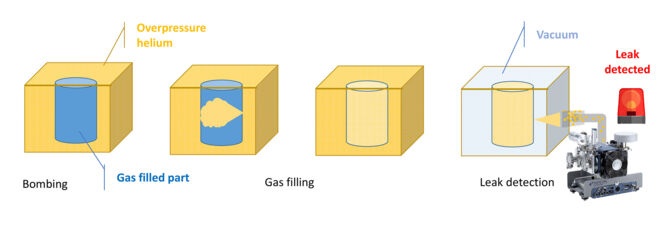

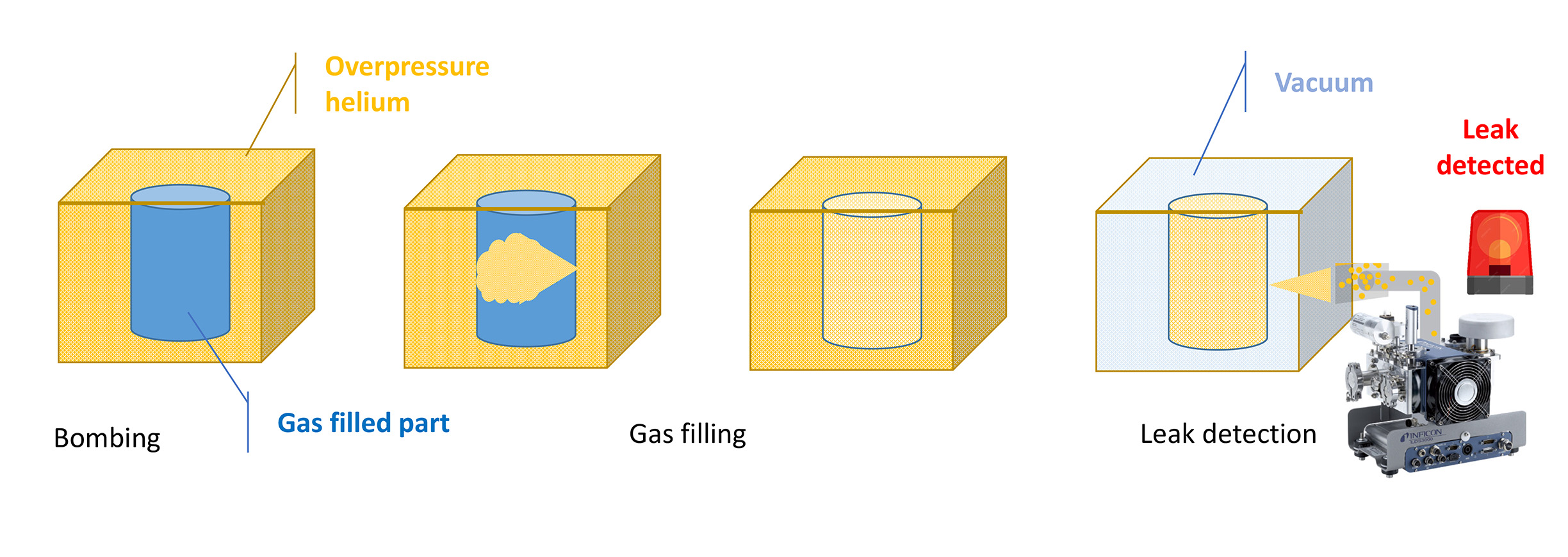

How does bombing of gas-filled parts work

For leak testing of hermetically sealed parts filled with gas, the part to be tested is placed in a chamber with a significant overpressure of helium. A helium pressure of 5 – 10 bar is very common for this step. If there is a leak, helium will enter the parts and over time the part will partly fill with helium. The process comes to an end when the part has reached the same pressure as the helium pressure in the bombing chamber and the part is filled with 80 - 90% helium concentration (for 5 to 10 bar helium bombing pressure). Then, the part will be placed in a vacuum chamber. If it has a leak, the helium / air mixture will escape again through the leak and will be detected by the leak detector. The process can be repeated very reliably.

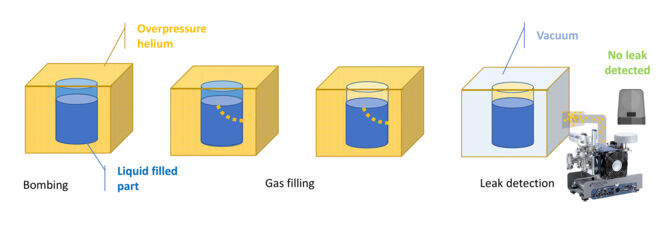

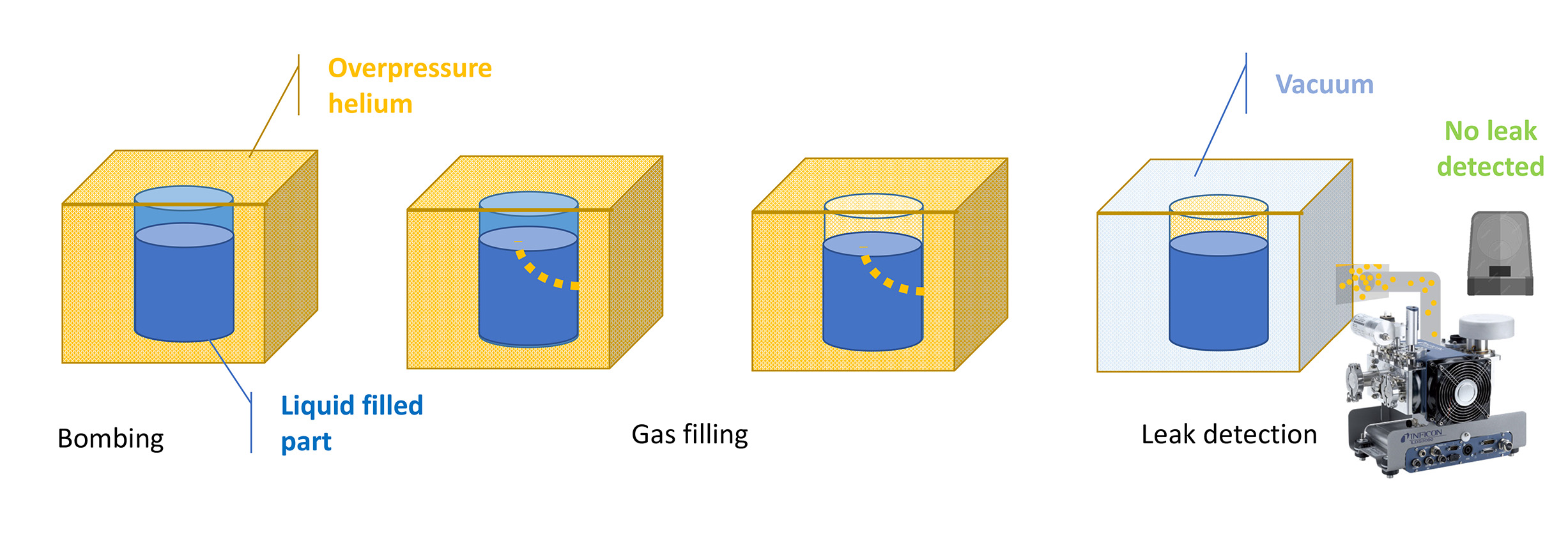

Helium bombing of liquid-filled parts like battey cells

In the case of liquid filled parts like battery cells filled with electrolyte, the helium will also enter the part due to the overpressure of helium in the bombing chamber. However, helium is a very light gas and will immediately bubble to the top of the part. Over time, helium will accumulate in the head space of the part until the pressure in the headspace has reached the same pressure as the helium pressure in the bombing chamber.

When the leaky part is placed in a vacuum chamber for subsequent leak testing, the helium cannot escape back out of the part as it did not stay in front of the leak, but raised to the top into the headspace. Only leaks in areas of the parts that are not wetted with the liquid (in this case electrolyte) can be detected. Any leaks wetted by electrolyte will not be detected. Hence, helium bombing does not offer a repeatable and reliable solution for leak testing of electrolyte filled battery cells.

How to test battery cells after electrolyte filling: Direct Electrolyte Leak Detection

A better way of leak testing electrolyte filled battery cells is the Direct Electrolyte Leak Detection (DELD) method. With DELD, sealed battery cells filled with electrolyte are placed in a vacuum chamber. As now the pressure inside the cells is higher than in the vacuum chamber (even for pouch cells), electrolyte is pulled out of the cells through any leaks. An ELT3000 PLUS Electrolyte Leak Detector connected to the vacuum chamber detects the evaporating solvent of the electrolyte as an indication of the leak. This process is very repeatable and reliable. It can be calibrated for traceable leak rates and offers a unique reliable way of detecting defective battery cells.

Want to learn more?

For more information, please contact us and visit the product page of our ELT3000 PLUS electrolyte leak detector.