Millimetric Precision in 3D Robotic Leak Testing

With the new I-Guide3D 350 scanner

Millimetric precision is crucial in fully automated leak test systems. On a refrigerator or heat pump production line for example, the position of all inspection points must be determined with millimetric accuracy. Manufacturing tolerances of +/- 1 cm for the position of solder joints have long been a challenge of robotic leak testing.

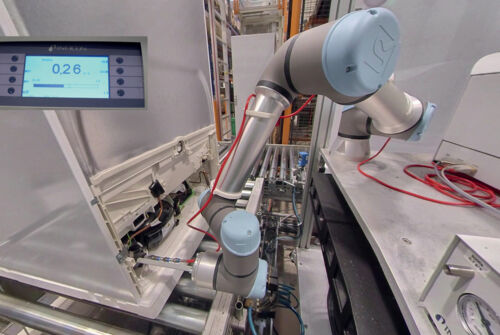

INFICON has developed the first fully automated 3D robotic leak testing system for your end-of-line inspection. The system includes the new I-Guide3D 350, an intelligent 3D sensor which helps to move the robot arm to the next inspection point, with millimeter precision, always along the shortest and fastest path. As a result, this 3D robotic leak testing system can meet the highest accuracy requirements of HVAC/R industry.

The 3D image recognition system from INFICON uses structured light by LED or laser. The structured light makes the scanner independent of brightness fluctuations in the ambient light. A software converts the 3D camera’s point cloud into XYZ coordinates so that it can control the robot arm optimally and without collisions.

I-Guide3D 350 is part of the Intelligent 3D Robotic Leak Testing System.

Four Components for Your Intelligent Test Station

The 3D Robotic Leak Testing System solution from INFICON includes four components that complement each other perfectly:

• Ecotec® E3000 – the multi-gas leak tester

• I-Guide3D 350 – the intelligent 3D Sensor

• I-Tip – the innovative and patented sniffer tip

• Calibration leak – our test leak for fully automated calibration

For more information about our 3D Robotic Leak Testing System download the product brochure or contact our leak detection experts.