Improving Quality in Refrigeration Manufacturing

Accurate robotic leak detection on refrigerators with 3D scanner

In the European Union, every refrigerator is required by law to undergo a leak test at the end of the manufacturing process. To streamline this process, more and more refrigerator manufacturers are looking for automated solutions. INFICON and their partner have collaboratively developed an innovative system for this task. This system efficiently checks the precise location of solder joints on the back of the refrigerator. Using a specially designed laser light and high-resolution cameras, the system generates a 3D point cloud of the scanned space, identifying and verifying the relevant solder joints with speed and accuracy.

The goal is to improve both productivity and quality

Leak detection requirements in the refrigeration industry are stringent, primarily to prevent the release of climate-damaging refrigerants into the environment. In addition, refrigerant loss can result in reduced cooling capacity and increased energy consumption. The vulnerable points in the cooling lines are the soldered joints at the back of the refrigerator, where the accessible refrigerant circuit lines run. The goal is to efficiently find any leaks and improve both productivity and quality.

Precision in approaching the solder joint

Typically, in automated test systems, solder joints located on the rear of a refrigerator are difficult for the robot arm to reach due to structural constraints. The assembly of coolant lines allows for manufacturing tolerances of +/-1cm in all directions, causing the position of solder joints to vary from device to device. This variability makes localization impossible with a conventional CAD-based 3D vision system. Another challenge is that the manually bent components of the coolant line, which are critical to soldering, are never identical in shape. This requires dynamic, real-time localization rather than reliance on CAD data.

Accuracy in approaching the soldered joint is essential to ensure precise alignment to the sniffer tip of the leak detection system.

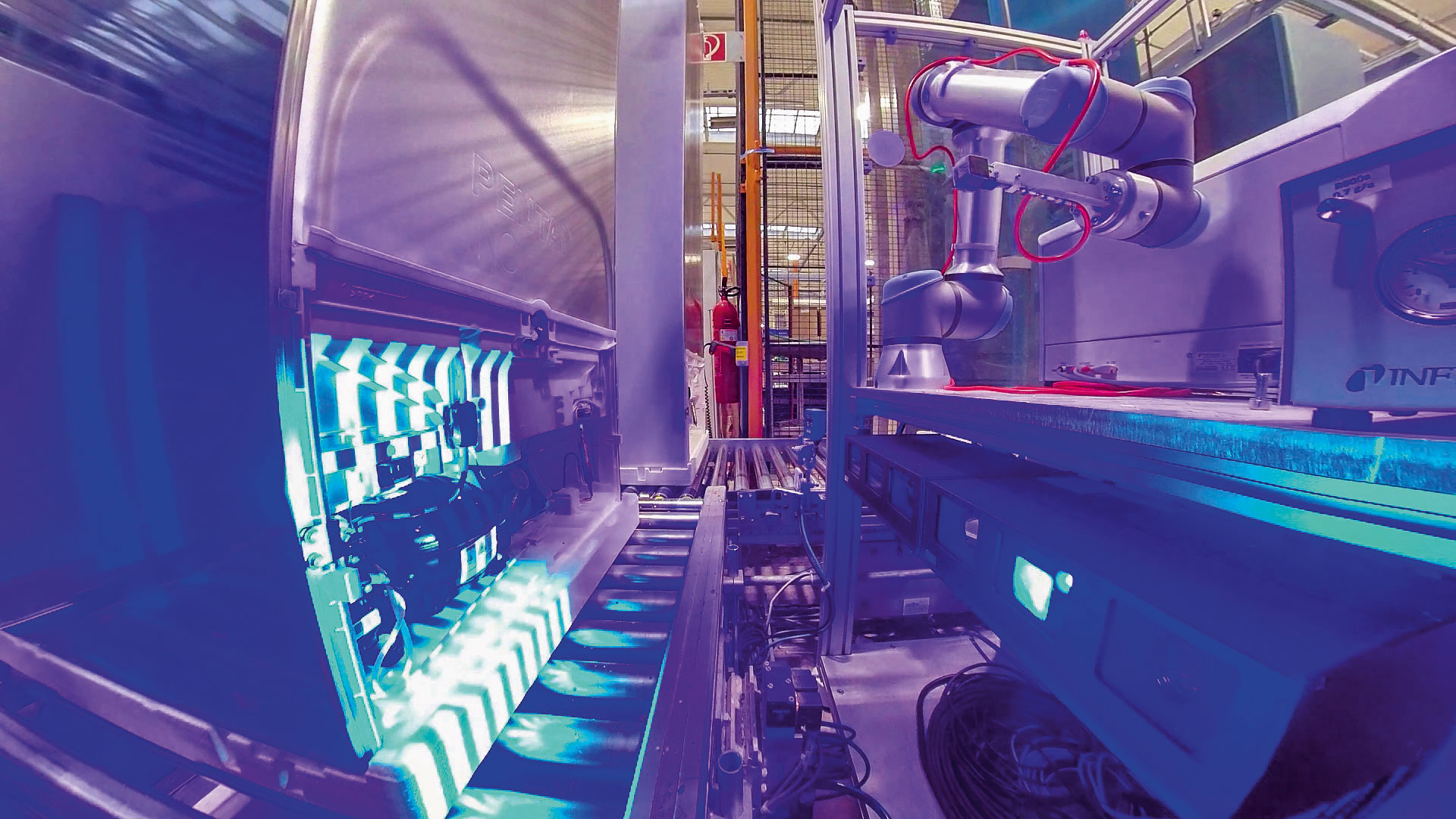

The solution from INFICON

The 3D Robotic Leak Testing System from INFICON locates very small leaks on pipes with millimetric precision. The system includes a leak detector, equipped with a sniffer tip designed specifically for automation, and a 3D image recognition system.

Determining the precise location of the solder joints to test is where the innovative 3D image recognition system comes in. “Operating in real time, the image recognition system visually detects inspection points on the surface of the coolant lines within the generated 3D point cloud. The system captures and stores individual coordinates and guides the robot arm with the sniffer tip through the inspection points," explains Volker Trieb. “Specially developed software equipped with robot path planning and collision-monitored robot guidance prevents collisions with the sniffer tip, solving a critical challenge beyond precision.”

Typically, there are six to twelve soldered joints on the back of a refrigerator that are tested for leaks. The system not only handles this dynamic localization, but also incorporates optimized path planning to ensure that the leak test is performed within the set cycle time.

The compact robot cell, including the 3D system, occupies a space comparable to that of a human operator. The image recognition system operates autonomously regardless of ambient light conditions, effectively handling darkness, daylight and artificial lighting.

“A trained employee can easily reconfigure the intelligent system for new refrigerator models, eliminating the need for external technicians. This empowers manufacturers to take control and ensure that no leaking refrigerators make it to market," adds Volker Trieb.

By providing accurate and reliable leak detection, the robotic leak detection system from INFICON ensures the integrity of joints on the back of refrigerators, while improving quality and supporting the industry's commitment to environmental responsibility.

Interested in learning more about the solution from INFICON?

If you want to automate your manual leak test and learn more on how to perform safe and operator-independent leak tests on HVAC/R components, look at our robotic sniffing video or watch our webinar.