Speed up your Vacuum Leak Testing

The automotive industry is constantly striving to reduce cost without sacrificing product quality. One means of reducing the cost is to increase the throughput of leak testing. Many automotive components are tested in automated helium vacuum leak testing systems. Reducing the cycle time of the leak test directly leads to higher throughput of the testing system.

INFICON introduces a new software feature to the LDS3000 product line that helps speed up the cycle time: I·Zero 3.0 is an intelligent helium background suppression that allows you to start the measurement cycle earlier, when the helium background is still declining – without the risk of missing leaks or misreading larger leak rate values.

How does it work?

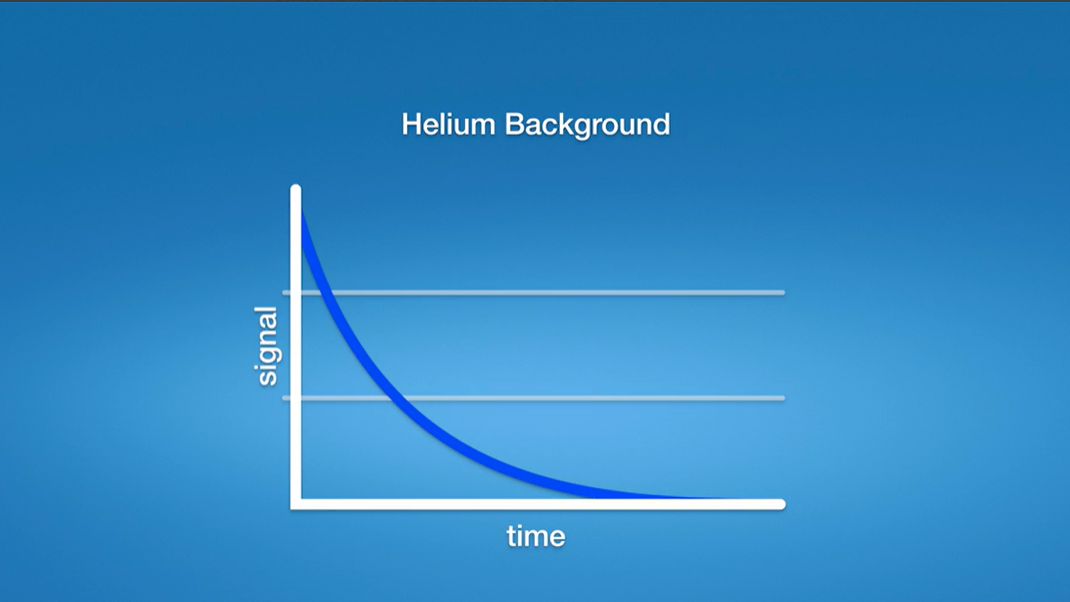

The new I·Zero 3.0 constantly monitors the declining helium background and together with some intelligent algorithms foresees the further decline of the background signal. It then takes the foreseen background decline into account and constantly adopts the amount of background signal to be deducted.

A detailed explanation of the algorithm is given in the below video:

What are the benefits of the new I·Zero 3.0 algorithm?

1. Faster cycle times

I·Zero 3.0 allows you to start a measurement much earlier than before – while the background signal is still decreasing. This will be especially beneficial the larger the free volume of the vacuum chamber (i.e., volume of the test chamber minus the volume of the part). Larger chambers typically have larger pump down times until a stable background is achieved. With I·Zero 3.0 you can now start measuring significantly faster as you do not have to wait for the background to completely stabilize.

Example:

In a real-world application a test system was designed to detect a 1*10-5 mbar·l/s leak in a 450liter chamber. With the use of I·Zero 3.0, the cycle time from pump down to leak rate result could be reduced from 31 seconds to 20 seconds – a reduction of 11 seconds or 35%.

Examples of large parts include fuel tanks, hydrogen tanks, DEF tanks, battery trays, and many more.

2. Lower cost test systems

In return, I·Zero 3.0 can also be used to reduce the cost of a testing system. In the past, for a quick cycle time it was mandatory to use large pumps with high pumping speed to quickly pump down the helium background. I·Zero 3.0 is an innovative, smart approach to system design: with I·Zero 3.0, smaller, lower cost pumps can be employed for the same cycle time as opposed to larger, more costly pumps used before.

3. Testing of multi-channel parts

I·Zero 3.0 is also beneficial for all applications where contamination of the background is almost unavoidable, like for multi-channel testing of parts. Examples of multi-channel testing includes:

- testing of any components which must be leak safe to the outside but also include cooling loops like water-cooled electric motors for electric drive trains, and

- whenever any two or more cavities must be tested for leaks to the outside but also for crossover leakage, e.g., testing of bipolar plates (where the air / oxygen, the hydrogen and the cooling channel needs to be tested).

When will I·Zero 3.0 be available to customers?

The new I·Zero 3.0 has been implemented with the software release V2.86 for all LDS3000 leak detectors as a BETA software function. I· Zero 3.0 was tested for 12 months at select customers before it was implemented as a BETA function.

We are currently collecting feedback from BETA users with respect to ease of use and touch and feel of the functionality. A full version of I· Zero 3.0 will be launched with the next software release for the LDS3000 in Q4/2022.

If you want to learn more about the new I·Zero 3.0 software, make sure not to miss our free webinar on Oct 11, 2022. You can register for it directly here and through the INFICON Academy section of our website. For even faster access, please contact us.