Leak Detection in Hydrogen Applications

From Production to Consumption

Are you interested in improving the safety and efficiency of your hydrogen systems?

- Are you responsible for ensuring efficient hydrogen production, storage or distribution?

- Are you looking for cutting-edge solutions to maintain high safety standards throughout all stages?

- Do you need to ensure that hydrogen loss is minimized in your products and operations?

The global energy landscape is rapidly evolving, offering companies unparalleled opportunities to shape the future of hydrogen applications. From hydrogen production and storage to applications where it is consumed, such as fuel cell vehicles and electricity generation, leak detection is crucial for ensuring safe, reliable, and efficient operations across the entire supply chain.

This journey will only succeed through advanced leak detection solutions – in collaboration with INFICON.

INFICON - Your Trusted Partner in Leak Detection

Hydrogen leak detectors are perfect for final testing with hydrogen tracer gas in production and for testing systems and components using pure hydrogen. For more demanding leak testing needs, INFICON also offers advanced alternatives like helium or vacuum leak testing. Our product portfolio includes proven solutions for all types of components, systems, and production volumes.

INFICON is a global supplier of leak detection and gas analysis solutions, with decades of expertise in identifying hydrogen gas even at the lowest concentrations. Our technologies support hydrogen applications in sectors such as:

Safety and Efficiency Along the Entire Chain

1. Hydrogen Production

Hydrogen generation, whether through electrolysis or reforming processes, requires strict safety measures due to the flammable nature of hydrogen gas. The electrolyzer stack is the core component where water is split into hydrogen and oxygen using electricity. It contains numerous cells with membranes, electrodes, and seals. The hydrogen gas produced must be contained to prevent dangerous leaks that could compromise safety or result in costly losses. In most hydrogen production facilities, hydrogen is compressed for storage or further use. Regularly inspecting compressor housings, seals and pistons for leaks ensures that compressed hydrogen is handled safely.

INFICON's advanced leak detection technology enables both state-of-the-art solutions for quality assurance of hydrogen production systems and components as well as real-time hydrogen detection of even the smallest leaks, minimizing the risk of accidents and ensuring the integrity of production systems.

2. Hydrogen Distribution

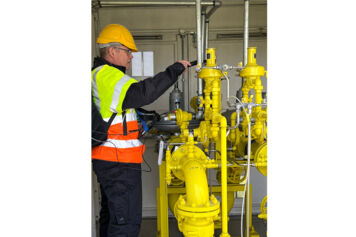

Once it is produced in the electrolyzer, hydrogen is transported through piping and gas manifolds. Leak detection is essential along these pathways because hydrogen, due to its tiny molecular size, can escape even through the tiniest holes. Fittings, joints, and valves are examples of potential points where hydrogen may leak. Regular monitoring of these assets helps prevent small leaks from developing into major hazards and resulting in the loss of valuable resources.

INFICON offers a variety of leak detectors to identify even the smallest leaks on pipes, joints and valves, no matter if you are running a grid with pure or blended hydrogen grid.

3. Hydrogen Storage

As the amount of hydrogen applications grows, so does the need for safe and reliable storage solutions. Storage systems must be carefully monitored for leaks especially under high pressure. Whether hydrogen is stored in its gaseous or liquid form, tanks and buffer systems should be regularly inspected to ensure their structural integrity and prevent losses.

Leak detectors from INFICON meet the highest safety requirements to ensure that tanks, cylinders and storage systems in general remain secure.

4. Hydrogen Consumption

Hydrogen consumption spans across multiple industries and applications, reflecting its versatility as a clean energy carrier. The use of hydrogen in fuel cells, industrial processes, energy generation systems and transportation requires a high level of safety and reliability, as undetected leaks can result in reduced efficiency and safety concerns.

INFICON provides leak detection solutions tailored to the end-use stage of hydrogen, ensuring that equipment and systems using hydrogen operate without leakage.

Related News

Hydrogen has significant potential to help decarbonize our economy and to become the fuel of the future. INFICON has world-leading expertise to help make this vision a reality.

EX-certified Instruments for safe leak detection

Monitor hydrogen in pipeline-quality natural gas with Micro GC Fusion®. This compact gas chromatograph ensures precise fuel composition analysis and optimal hydrogen detection using helium and argon for accurate results.